As the manufacturing industry is expanding quickly, improving production output is important. Machinery & equipment ERP Software can help deliver exactly that for manufacturers everywhere. It is a game-changing solution created for the manufacturing industry.

This article explores ERP for industrial equipment & machinery manufacturers, discussing its capabilities within the manufacturing sector and how it increases productivity and growth.

Cloud-Based ERP Software for Machinery & Equipment

Cloud-based ERP helps the Industrial Machinery & Equipment industry. It is a complete, automatic solution designed to meet your industry-specific needs. The Industrial Machinery ERP is your key to achieving smooth operations while improving overall business performance. ERP Software will transform and upgrade your business processes and give you smooth operations.

The ERP software for the machinery and equipment industry is made with a unique approach focused on manufacturers. This cloud-based solution is flexible and scalable and fits into all modes of production, suited not only to manufacturing but also to other parts of the manufacturing process.

Managing the complex network of inventories, machines, and spare parts in the machinery and equipment manufacturing industry can be challenging. However, with ERP Software, handling multi-level production and workflow management becomes simple and easy. You can easily keep track of your real-time inventory, schedule Material Requirements Planning (MRP), and manage your shop floor functions effortlessly. The machinery & equipment ERP Software provides you with a clear understanding of the cost of each raw material, allowing you to stand out as the best machinery and equipment manufacturer for your clients.

Say goodbye to administrative difficulties with advanced ERP solutions for the Machinery and Equipment industry. Experience the comfort of task management and complete business control. The ERP Software offers a modern and affordable manufacturing/production process for machinery & equipment tasks.

ERP Software Solve all Machinery & Equipment Problems Effortlessly

Here is how ERP Software helps solve all machinery and equipment problems easily:

1. Has Innovative Software Design

ERP software is designed with a detailed approach from start to finish, providing innovation at every stage.

2. Helps Improve Production Planning

ERP software helps with better operations through record-keeping for job records, increasing workflow performance.

3. Helps In Inventory Management

This software overcomes the challenge of large inventories head-on, reducing waste and increasing resource usage.

4. Provides Accurate and Timely Quotations

ERP software helps with real-time solutions for accurate and timely quotations, providing transparent and quick customer communication.

5. Offers Improved Supply Chain Function

ERP software helps maintain stock availability for hassle-free operations, promoting quick response to meet market demands.

6. Promotes Quality Control

This software helps maintain minimum product standards through in-depth checks, making sure quality is maintained in every manufactured product.

7. Offers Quick Tracking

ERP software helps identify defective parts right from the beginning of the procurement process, leading to an active approach to quality assurance.

8. Comes With Integrated Systems

ERP tools are all about collaboration across all internal business units for smooth operations. It helps promote collaboration and easy communication across different departments.

9. Helps Tracking Customer Feedback

ERP software helps improve customer experience by tracking their feedback, which brings continuous improvement across all departments.

10. Helps With Machinery and Equipment Lifecycle

ERP software offers complete support for every stage of product development, offering high performance and safety throughout the product lifecycle.

11. Helps Follow Sustainability Practices

Saving natural resources and energy for a greener future is a must. And ERP software is developed keeping environmental safety in mind, which helps complete operations following all eco-friendly principles.

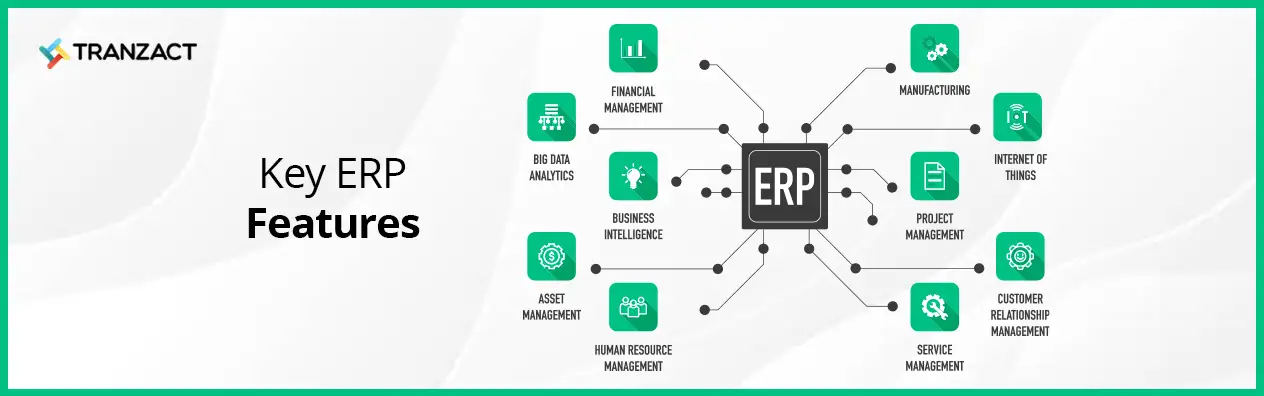

Key Features of ERP for Machinery and Equipment Industry

Here are some key features of the machinery & equipment ERP Software:

- Multi-Level Bill of Materials (BOM): Helps to manage complex manufacturing processes easily, maintaining a structured approach from design to execution.

- Production Schedule Mastery: Helps to improve workflow and boost productivity through an automatic production scheduling system that keeps operations on track.

- Workstation/Machine Planning: Helps to improve operations at every workstation, promoting a smooth and successful production environment.

- Multiple Production Houses: Helps to manage multiple production facilities effortlessly, maintaining a uniform approach across multiple locations.

- Job-Work/Outsourced Management: Helps to easily coordinate and monitor outsourced tasks, resulting in an organized and productive supply chain.

- Multiple Warehouse Management: Helps to easily manage and track inventory across multiple warehouses, improving resource management.

- Batched Inventory Excellence: Helps to increase inventory control through a batched inventory system, maintaining accuracy and quick tracking.

- Quick Stock/Inventory Balance: Helps to stay ahead of inventory changes with real-time monitoring, allowing quick adjustments to maintain the right stock levels.

- Quality Check/Control: Helps to maintain quality standards with a complete quality check/control system, making sure every product meets the required standards.

Challenges of Machinery and Equipment Industry

There are many challenges to deal with in the machinery and equipment industry. Let’s see the most common challenges and how machinery & equipment ERP Software helps deal with them:

1. Inventory Management

As a manufacturer, handling a large inventory can be a major challenge. A Machinery ERP Software offers a solution to easily control real-time inventory, identify shortages, and improve rolling stock.

2. Production Planning

You need detailed planning and tracking for successful production management. An ERP Software supports timely manufacturing and delivery by showing production progress, syncing resources, and addressing challenges promptly.

3. Quotation Management

Manufacturers often struggle with low-cost and reliable quotes. An ERP Software resolves real-time challenges, improving success rates and preventing financial losses due to high-low margins.

4. Quality Control & Traceability

Maintaining order quality is important for manufacturers. An ERP Software guarantees adherence to minimum standards and can identify damaged parts from manufacturing to delivery, resulting in customer satisfaction.

Simplify Your Manufacturing Process With TranZact’s ERP Software

Working in the machinery and equipment industry requires having software that increases production capabilities. With TranZact's advanced ERP software, you can improve productivity, boost operations, and gain complete control over your business. TranZact allows Indian SMEs to succeed in manufacturing, providing a single solution for end-to-end process management.

FAQs on ERP Software for Machinery and Equipment Industry

Q1. What is ERP software for the Machinery and Equipment Industry?

ERP software for the Machinery and Equipment Industry is a solution that is designed to simplify various business processes. It includes features like inventory management, production planning, and quality control that improve overall operations.

Q2. How can ERP software benefit my machinery manufacturing business?

ERP software brings cost savings by speeding up processes, increasing resource allocation, and providing real-time insights. It improves production planning, inventory control, and quality management, ultimately leading to higher profit.

Q3. Is ERP software customizable for specific industry needs?

Yes, modern ERP solutions, like those made for the Machinery and Equipment Industry, are customizable. They can be adapted to suit your business's unique requirements and processes, offering a personalized and effective solution.

Q4. How does ERP software handle inventory challenges in the machinery sector?

ERP software easily manages large inventories by providing real-time visibility, tracking stock levels, and maintaining inventory balance. It helps identify shortages, prevent overstock, and promote a smooth workflow.

Q5. Can ERP software help in quality control and traceability?

Absolutely. ERP systems in the Machinery and Equipment Industry have features to maintain quality standards, conduct checks, and allow traceability. This makes sure that all products meet the desired quality requirements and allows quick identification of broken parts.

Q6. What role does ERP software play in sustainability for machinery manufacturing?

ERP software contributes to sustainability by improving resource usage, reducing waste, and adhering to environmental regulations. It helps preserve natural resources and energy, providing your machinery manufacturing business with eco-friendly practices.