Technology-enabled tools, such as manufacturing ERP software, are reshaping the manufacturing industry by driving the need for increased automation. This demand for automation extends to various aspects of the manufacturing process, including design, production, marketing, and sales.

Automation and digitization of manufacturing processes enhance productivity, and efficiency, for informed decision-making and improved sales. Enterprise Resource Planning (ERP) software acts as a catalyst in this process, providing a centralized platform to streamline end-to-end manufacturing operations.

Read on to know more about manufacturing ERP Software and why it's important for your business. This article will also help you learn about manufacturing ERP modules, the benefits of manufacturing ERP software, and the difference between standard ERP and manufacturing ERP.

What Is Manufacturing ERP Software?

A manufacturing ERP software is a collective suite of automated processes to plan, manage and execute day-to-day business operations. It caters to the specific needs of a manufacturing company and provides an updated and integrated view of data for business owners.

By bringing together multiple business functions, it ensures smooth and error-free operations. An optimized ERP software for the manufacturing industry covers different functional areas from sourcing and inventory acquisition to materials planning and production. It also oversees quality testing and distribution. Thus, ERP software for a manufacturing business provides a 360-degree view of the manufacturing business from the shop floor to the top floor.

Read Also - What Is Agile Manufacturing?

How Does Manufacturing ERP Software Work?

ERP software for the manufacturing industry integrates with shared databases and applications of a manufacturing business. As a unified business management platform, it simplifies everyday manufacturing operations and digitizes core functions such as sales, purchases, inventory, and production.

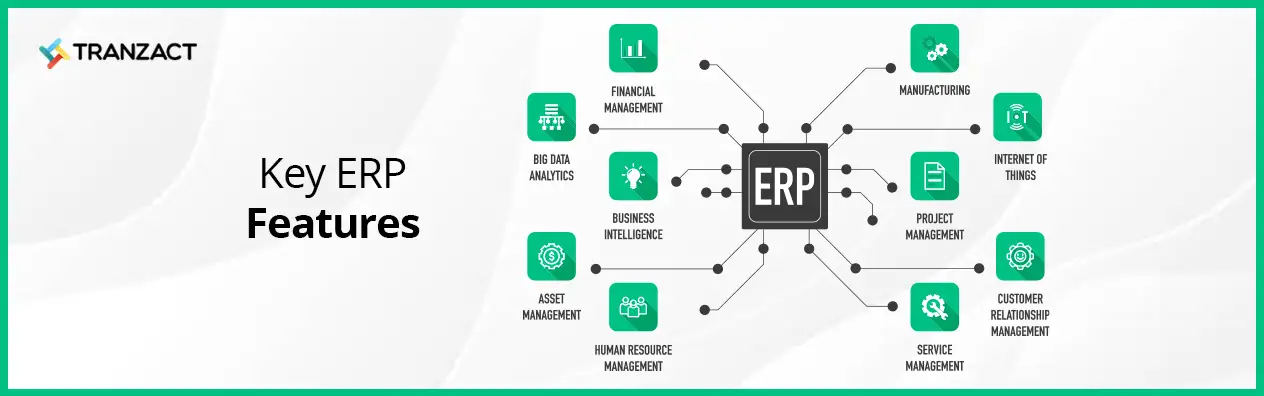

ERP for the manufacturing industry functions through these key modules:

Inventory Management

Inventory management abilities in manufacturing ERP software help to track real-time inventory status, readiness, and location of products or materials needed. It detects shortages and fulfills requirements proactively to avoid unwanted delays.

Business Intelligence

ERP software for the manufacturing industry enables access to smart business dashboards with daily and weekly data like sales orders, purchases, invoices, and more for growth tracking across all functions.

Transactions

With a process manufacturing ERP software all transactions, whether sales or purchases, can be created easily and their live status can be viewed.

Production Scheduling

Advanced planning and scheduling capabilities help in evaluating what resources may be required at what point in time in the production pipeline.

Quality Testing and Compliance

This module within manufacturing ERP software systems ensures products meet customer specifications and proactively identifies quality or compliance issues.

CRM Integration

ERP for the manufacturing industry allows management to get real-time insights into customer activities and the sales funnel, enabling better customer service and support.

**Read Also - Difference Between Manufacturing and Production Explained(())

Benefits of Manufacturing ERP Software

There are various short-term and long-term benefits of ERP for manufacturing companies, let's read about them here:

Enhanced Productivity and Operational Efficiency

Integration of all core manufacturing ERP modules ensure a seamless flow of transactions, from order creation to bill generation.

360-degree Visibility

A single data source in an ERP database provides centralized visibility into cross-functional manufacturing processes.

Quick Market Response

Real-time reporting and dashboards with manufacturing ERP modules enable stakeholders to quickly act on the insights for swift decision-making. Detailed insights help reduce forecasting errors and build on new growth opportunities, as and when available.

Agility and Collaboration

A common control system within process manufacturing ERP software enables better collaboration between different business units. It brings in the agility needed for ever-changing business requirements.

Risk Mitigation

ERP for the manufacturing industry provides the right controls to identify and predict and mitigate business risks, ahead of time.

Regulatory Compliance

Manufacturing ERP software systems enable consistent documentation and audit trail of system records, increasing confidence by meeting regulatory compliance needs.

Better ROI

A robust manufacturing ERP software helps reduce operational costs, increases employee productivity, and therefore, increases the return on investment (ROI).

What Is the Difference Between Standard ERP and Manufacturing ERP?

Standard ERP systems provide generic functions such as sales, accounting, finance, and human resources. But they are designed with an umbrella approach for all industries. They lack the tools required to capture critical business data needed for manufacturing insights.

A manufacturing ERP fills these gaps and caters to the manufacturing industry specifically. Here's a look at their key differences:

| Standard ERP | Manufacturing ERP | |

|---|---|---|

| Customization | It's not designed for the manufacturing industry. Businesses may need to purchase expensive add-ons to meet requirements. | Manufacturing ERP software systems are tailored for the manufacturing industry, and thereby, offer more value to manufacturers. |

| Functions | It fulfills basic needs. But it might have lesser or excess functions not required by a manufacturing business. | It contains all the required functions for a manufacturing business such as production, inventory, order management, and more. |

| Upgradations | Unnecessary standard ERP updates may be expensive and hinder productivity. | All upgrades are based on the problems being faced by manufacturers in particular. So, with each upgrade, the aim is to streamline the process for better returns. |

Force-fitting a standard, all-in-one ERP solution is not the best idea for managing manufacturing business processes. Thus, it becomes more important for organizations to invest in manufacturing ERP software, preferably cloud-based manufacturing ERP software. The latter supports dynamic business requirements demanded by today's SME manufacturing companies.

When Should a Company Start Using Manufacturing ERP Software?

As production demand increases, manual processes and standalone programs are incapable to support the growth trajectory of a manufacturing business. Businesses require the right tools to address problems like optimum resource planning, supply chain management, and product quality management. It's important to adopt an ERP system that offers valued solutions like Bill of Material (BOM) management, Material Requirements Planning (MRP), finished goods testing, production scheduling, and more. Keeping these factors in mind, the following are a few early indicators for your enterprise to start using process manufacturing ERP software:

Poor data management because of disparate systems

Manufacturing businesses need hassle-free access to data. However, business units often operate in silos, making daily data processing and communication among departments time-consuming and inefficient.

Frequent issues with production scheduling

On-time order delivery drives the success and reputation of a manufacturing enterprise. It is key to increased customer satisfaction which leads to business profitability. Frequent production rescheduling because of planning and operational issues may lead to demand and supply mismatches.

Inaccurate reporting and missing insights

Moreover, if your internal teams are struggling to generate accurate reports and actionable insights from data, then adopting a manufacturing ERP system will simplify these challenges for your business. The best ERP for manufacturing integrates various modules on a real-time basis enabling data sharing between teams and consolidation of data to generate meaningful reports.

Read Also - Manufacturing Process Planning Explained

Which Is the Best Manufacturing ERP Software?

The best ERP software for manufacturing in India is one that is designed specifically for manufacturing companies and is trusted by fellow industry members. Your choice of manufacturing ERP software will depend on your organization's size, functions, and needs. You can evaluate your decision, based on how well the system fits into your working model and if it ties together with existing business processes. TranZact offers flexible ERP solutions and is trusted by over 10,000+ Indian SME manufacturers. As a cloud-based digital transformation tool, designed specifically for Indian SME manufacturers, it digitizes end-to-end business processes from customer inquiry to dispatch. TranZact’s ERP for the manufacturing industry integrates quotations, inventory, purchases, sales, and production in a hassle-free and user-friendly manner. You can make informed decisions with real-time reporting and gain complete visibility into all business operations at one glance. Read more in the following section as it dives deeper into how TranZact works for manufacturing SMEs, and its key features.

Read Also - 25 Manufacturing Business Ideas in India

Features of TranZact Manufacturing ERP Software

The best ERP software for manufacturers provide competitive benefits for businesses. TranZact performs all ERP functions but is substantially more powerful than any other ERP tool for SMEs. Here's a list of key TranZact features for your reference:

Zero-effort and Intuitive Solution

TranZact enables a seamless one-click setup and integration with your current business operations. It brings together all core business functions like sales, purchases, production, and inventory with its centralized cloud platform.

By fully automating important activities performed by a manufacturing business, it brings down manual efforts significantly.

Tally and Excel Integration

Your accounting and administrative workforce can continue to use the tools they are comfortable with like Tally and Excel spreadsheets. TranZact comes with easy-to-use Tally and BUSY integration for accounting convenience and allows teams to export and import data from Excel without any difficulties.

GST-Compliant Documentation

As a manufacturing process management software, it offers invoicing and documentation solutions that are GST-compliant. You can create several important documents such as purchase orders, sales orders, challans, and goods received notes easily with TranZact.

Real-Time Operations

With its powerful cloud capabilities, it assists businesses in tracking quotations and conversions. It keeps a tab on purchases, production schedules, and MRP through automated notifications. And also provides managers with a chronological view of incoming and outgoing inventory.

Free Forever Plan

Most manufacturing ERP software solutions in the market require you to make an upfront investment before you try them. With TranZact, you don't need to pay anything for the base features to start with.

You can sign up for free and explore all base features for an unlimited free period. Once you see how well TranZact meets your business goals, you can decide to switch to advanced plans.

Top Notch Support

TranZact supports your business-critical workflows with a dedicated customer support system. It offers dedicated lifetime free support for both free and paid plans. Other key functions offered by the tool include production management, multilevel BOM, finished goods testing, shipping assistance, payments support, transactions dashboard, inventory tracking, and work order monitoring among other features.

Read Also - What Is Inventory? Definition, Types, and Examples

Implement a Result-Oriented Manufacturing ERP Software

As we've seen, manufacturing ERP systems are a necessity, especially for SME businesses to remain agile and competitive within the industry. The correct choice of ERP software that understands your business requirements and in-house processes, will resolve your operational concerns and make decision-making significantly easier.

ERP solutions from TranZact not only centralize all operations with ease but also help manufacturers to adapt to change and disruptions effectively. It’s very easy to use and also quickly implementable. It enables manufacturing companies to reduce costs, gain visibility, exercise better control, and maximize ROI year on year!

FAQs on Manufacturing ERP Software

1. Which ERP software is used in the manufacturing industry?

TranZact is the most intuitive and popularly used software providing ERP solutions for the manufacturing industry. It automates sales, purchases, quotations, inventory, and production, and integrates with commonly used accounting and logistics software as well.

2. Is TranZact an ERP system?

TranZact provides advanced ERP solutions but is also exceptionally more impactful and powerful than ordinary ERP software. It provides all functions of a comprehensive ERP but also does a lot more such as offering multilevel BOM, finished goods testing, and smart dashboards for reports and insights.

3. What are MRP and ERP in manufacturing?

MRP (Material Requirements Planning) is a system used in manufacturing to plan and manage the materials needed for production. ERP (Enterprise Resource Planning) is a broader system that integrates various business functions, including manufacturing, inventory, and material handling to streamline operations and enhance overall business performance.

4. What are the common manufacturing ERP features?

Common manufacturing ERP features include inventory management, production planning and scheduling, quality control, transactions and supply chain management, and accounting.

5. Does ERP include manufacturing?

Yes, ERP (Enterprise Resource Planning) typically includes manufacturing functionality as a core module. Manufacturing and production are critical components of many businesses, and ERP systems provide specific features to support manufacturing operations and processes.

6. Why is manufacturing ERP important?

Manufacturing ERP provides a holistic view of entire operations and processes, from quotations to production. The best ERP for a small business enables organizations to achieve greater operational efficiency. It provides 360-degree visibility into disparate processes along with centralized coordination and management.

7. What are the types of ERP implementations?

There are mainly three types of ERP systems that function with different deployment model options. The most common types of ERP systems are cloud ERP, on-premise ERP, and hybrid ERP. A cloud ERP is recommended as the best manufacturing ERP software as it is fully automated and offers high flexibility for businesses.

8. What are some key functional areas supported by manufacturing ERP systems?

Manufacturing ERP systems improve operational efficiency across key functionalities such as: o Transaction management - This includes a complete overview of quotations, sales, and purchases. o Production planning and Management - This includes Bill of Material (BOM) management, production scheduling, routing, and testing. o Supply Chain Management o Quality Assurance o Work Order Management

9. What are some Key Performance Indicators (KPIs) I can use to measure the success of manufacturing ERP systems?

Manufacturing ERP systems bring qualitative and quantitative benefits to the organization. Increased visibility, improved transparency, and a boost in decision-making are some benefits that can be realized. The key KPIs used to measure the success of your ERP systems are: o On-time deliveries o Manufacturing cost per unit o Capacity utilization o Customer returns o First pass yield