The chemical manufacturing industry involves production of chemical-based items. This includes a wide range of activities. From procuring the raw materials to turning them into finished goods, industries like pharmaceuticals, agriculture, and other household manufacturing need to follow numerous processes. ERP software for chemical industry plays an important role in simplifying the complex manufacturing process and improving operations and workflow management.

Implementing ERP software can help you stay updated with the laws for chemical usage and improve the accounting process. Let’s learn how ERP (Enterprise Resource Planning) contributes to sustainable chemical manufacturing practices to reduce environmental impact and increase productivity.

ERP For Chemical Industry | Chemical ERP Software

Chemical industry ERP allows better resource planning and simplifies manufacturing activities. It helps to identify the market trends and monitor the workflow and productivity. The ideal chemical manufacturing ERP allows manufacturers to monitor the potential challenges in the chemical industry and solve them before they get bigger.

The ERP software for chemical industry makes it easier to follow all the regulatory compliance and help in sustainable practice and growth. Chemical companies need the best ERP solution that can match their business operations.

It also helps them address challenges to make better decisions quickly. Taking the right approach can help chemical manufacturing businesses reduce costs in the supply chain, minimize errors in manual tasks, and improve customer service.

Importance Of ERP In The Chemical Manufacturing Industry

The chemical industry businesses dealing with dyes, paints, cement, pharmaceuticals, and similar needs to follow laws of chemical usage. They also need to meet government regulatory compliance and local laws to reduce the harmful effects on the environment. This is where the best ERP for chemical manufacturing helps companies promote the right way of production. It helps to simplify compliance that could be understood easily, improve supply chain management, and increase productivity.

Choosing the right chemical ERP software for your chemical manufacturing business can provide you with modules to automate your accounting process with the following factors.

- Batch tracking for high-risk materials.

- Real-time data to make informed decisions.

- Categorization of materials based on their flammability, boiling point, shelf life, and toxicity.

- Management of waste, byproducts, and junk produced.

- Visibility by tracking multiple locations, product performance, and supply chain management.

- Effective formulation management, grade distribution, and quality control by documenting the testing parameters.

- Perform quality inspections, document them, and keep track of supplies.

- Management of financial activities, such as keeping records of sales and purchases and creating invoices and bills.

Challenges Faced By Chemical Industry Manufacturers

Due to constant changes in the customers' preferences and chemical manufacturing trends, the chemical industry is becoming highly competitive. It is also creating multiple challenges, like meeting the growing demand and regulating the laws of the local and central government, which have been discussed below.

1. Regulatory Compliance challenges in identifying and handling substances safely that can harm the environment and humans.

2. Traceability And Management of multiple warehouses, supply chains, inventory, quality control, and more.

3. Risk Management of carbon footprint and issues in managing and controlling emissions and wastes that are sent to land or water bodies.

4. Inventory Visibility with accurate data on the inventory levels to avoid stock outs or overstocking. This interrupts the cashflow.

5. Quality Control challenges that potentially damages their brand reputation.

6. Data Handling And Reporting such as invoices, BOMs, POs, and more, and difficulty to create reports.

7. Supply Chain Management challenges to meet the deadline and execute production properly in rush orders.

Chemical Manufacturing ERP Software: Streamlining Complex Manufacturing

The best ERP software for chemical industry helps you maintain compliance needs during manufacturing processes. It helps to manage the formulas with laboratory calculation modules and analyze the cost with proper MRP (Material Requirement Planning) and packaging materials.

The chemical ERP solution’s inventory management system also contains batch tracking with a barcode system to easily manage the large volume of material processing. It offers a centralized dashboard that promotes visibility across inventory and connects physical inventory to system records for better documentation. The best ERP for chemical manufacturing allows the integration of Excel, other apps like Tally and modules for effective financial recordkeeping and management.

Essential ERP Modules For Chemical Manufacturing Industry

The ideal ERP software for chemical industry contains modules that help with operations like production scheduling, inventory tracking, and many more. Check out this list below:

- Production Management

- Warehouse Management

- Inventory Management

- Sales And Purchase

- MRP (Material Requirement Planning)

- Formulation Management

- Regulatory Compliance

- Quality Control

- Costing Analysis

- Finished Goods testing

- Documentation of all processes

Key Benefits Of ERP Software In Chemical Manufacturing

Chemical manufacturing businesses always look for ways to increase productivity while following all the regulatory laws to avoid any issues. Implementing the right ERP software for chemical companies helps to meet all regulatory compliance requirements and adapt to market changes, along with the following benefits.

- Workflow Improvement: Track and schedule manufacturing operations with production and inventory management systems and features like batch-tracking.

- Real-Time Monitoring: Monitor operations on a single dashboard with real-time analytics and reports.

- Production Improvement: Analyze historical data for better production planning and cost-saving in procurement.

- Industry Updates: Stay informed about market trends and legal changes with business intelligence modules with cloud ERP software.

- Recordkeeping Ease: Automate recordkeeping with software integration, creating and storing invoices and bills effortlessly.

Click this link to know more What Are the Benefits of ERP System?

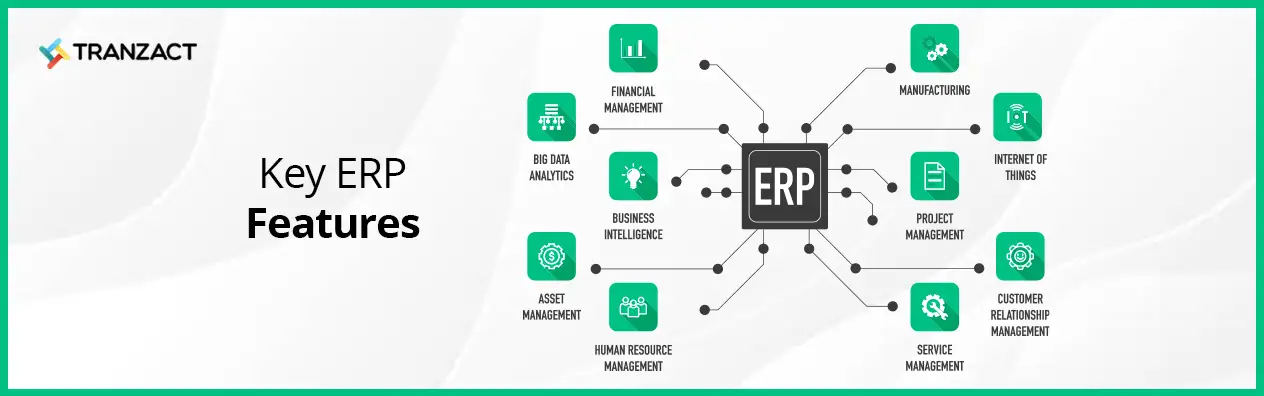

Key Features Of ERP Software For Chemical Industry

The ideal chemical industry erp software is one that can provide a variety of modules and functionality to improve product manufacturing. The erp system for chemical manufacturing should have the following features that help the SMEs.

- Should allow multi-level BOM creation to improve the chemical procurement process.

- Should provide a production planning system for easy scheduling and real-time work tracking.

- Should include a requisition and access control system for quick and easy approval of invoices and bills.

- Should have a system to track and manage multiple warehouses from a single dashboard.

- Should include batched inventory management for easy tracking through a barcode scanning system or RFID (Radio Frequency Identification) system.

- Should have regulatory compliance based on government laws and industry standards, and you must be given instant alerts when any changes occur.

- Should have total quality management to document all the measures of quality product checklist.

- CRM (Customer Relationship Management) system can help in lead management, sales forecast, order management, account management, and many more to improve the customer relationship.

Want to know What Are the Types of ERP Systems?

Implementation Of ERP Software In Chemical Manufacturing

Checmical ERP system helps manufacturers automate their production process by following industry standards. It is important that your ERP software for chemical industry should integrate with your existing system while effective data transfer with the following steps.

- Understand Your Chemical Business Requirement

- Set a budget to spend on ERP software for chemical industry

- List the vendors that provide ERP system that matches your requirements.

- Select the system that has all the modules and functionality to simplify your operations.

- Read online reviews of the selected options.

- Try the free or trail version of selected options before proceeding with paid version.

- Transfer your organization's existing data to the new system.

- Conduct the testing procedure to identify potential issues and solve them before fully implementing.

- Consider implementing the installation process under expert guidance.

- Train your employees about the functionalities of the chemical ERP system.

Learn more about the 8 ERP Implementation Challenges and Risks.

Choosing The Best ERP For Chemical Manufacturing

The right ERP software should support your long-term goal and other factors that we have mentioned below to scale your business.

- Look for industry-specific features like regulatory compliance, which include features like batch tracking, formulation management, material control, accounting modules, and quality control to improve your operational performance.

- Consider choosing a chemical manufacturing ERP that has the ability to improve the workflow and scale your chemical business.

- The software must offer customizable modules to meet your unique business needs and easily integrate with your existing system.

- Look for cloud ERP software for chemical industry that offers to collaborate with different departments and share files and other valuable information using a single device.

- Choose the software that offers real-time visibility into operations for better demand forecasting and production planning.

- Analyze the vendor’s reputation and the support they offer to the customers.

- Check the compliance and security features for formulation management, data protection, and privacy measures.

- Consider implementing cloud ERP software chemical manufacturing that integrates advanced technologies like IoT (Internet of Things) and operates on your mobile device.

Check out the 5 Best ERP Software for Manufacturers in 2024.

Conclusion

ERP in the chemical manufacturing industry plays an important role in meeting regulatory compliance and improving productivity. But for an Indian SME chemical manufacturer, ERP might be expensive and difficult to implement. TranZact offers effective modules of ERP software for chemical industry that simplifies manufacturing operations with production management.

With TranZact, you can easily automate your inventory tracking with real-time data access and have complete visibility of your supply chain at a place.It helps you to document quality measures, simplify accounting operations, and easily create bills, purchase orders, invoices, and other documents.

Choose TranZact now to improve the overall operations of your chemical manufacturing business and stay forward in your industry.

FAQs

1. What is ERP for Chemical Manufacturing?

ERP for Chemical Manufacturing is a software solution designed to streamline production, inventory, and compliance processes, making sure efficient operations and regulatory compliance. It integrates various functions like production planning, real-time monitoring, and recordkeeping in one place.

2. What is ERP software for the chemical industry?

ERP software for the chemical industry is a digital solution that helps to automate manufacturing activities. It provides real-time information to analyze the challenges and make better decisions to solve them with no delays.

3. How does ERP software benefit chemical manufacturing companies?

ERP software benefits chemical manufacturing companies by simplifying production, inventory, and supply chain management while making sure regulatory compliance and efficient warehouse operations.

4. What are the key features of chemical manufacturing ERP software?

The key features of chemical manufacturing ERP software are:

- Batch Tracking

- Barcode Features

- Chemical Formulation Management

- Regulatory Compliance Management

- Multi-level BOM Creation

- Quality Control Management

- MRP (Material Requirement Planning)

- CRM (Customer Relationship Management)

5. How do I choose the best ERP for chemical manufacturing?

You can choose the best ERP for chemical manufacturing by considering the following factors:

- Industry Specific Features

- Scalability

- Customizable Modules

- Real-Time Visibility

- Security Features

- Integration Capability

- Vendor's Support

6. Can ERP software help with regulatory compliance in the chemical industry?

Yes, ERP software can help with regulatory compliance in the chemical industry by automating regular reporting of industry changes.

7. Can ERP Improve Supply Chain Efficiency in the Chemical Industry?

Yes, ERP can improve supply chain efficiency in the chemical industry by simplifying the procurement process, scheduling production, and improving inventory management for on-time order dispatch.

8. Is ERP Suitable for Both Small and Large Chemical Companies?

Yes, ERP is suitable for both small and large chemical companies due to its adaptability, effective functionality, and scalable modules.

9. Are Cloud-based ERP Solutions Suitable for the Chemical Industry?

Yes, cloud-based ERP solutions are suitable for the chemical industry as they provide real-time access to valuable data, reduce production costs, and promote scientific and standard management.

10. How Does ERP Contribute to Data-driven Decision-making in the Chemical Sector?

ERP contributes to data-driven decision-making in the chemical sector because of real-time reporting and analytics on market trends and provides complete visibility of business operations.