When you try to automate a manufacturing business, many difficult questions come up. Why is ERP important, how is it different from other solutions, and which ERP system should we use? If you are a manufacturer, you must have faced these challenges at least once. In this blog, we will learn about what is ERP system and its importance, uses and benefits.

What Is ERP (Enterprise Resource Planning)?

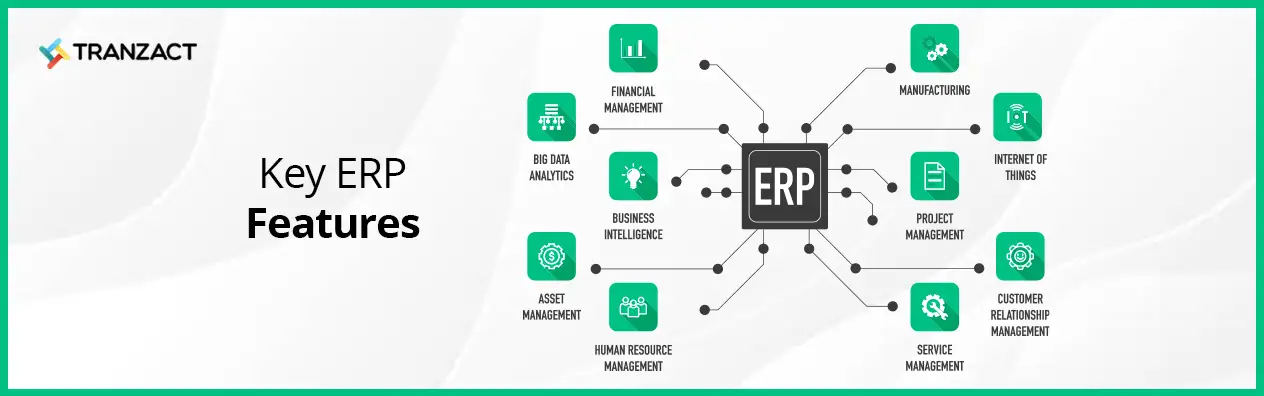

Enterprise Resource Planning (ERP) software helps you manage different parts of your business and streamline them. It might sound like other products but its special features make it a unique player in the software market. Enterprise Resource Planning is a type of software, which companies use to plan and manage their day-to-day activities. It can manage:

- manufacturing

- financials

- supply chain

- accounting

- procurement

- projects

- customer relationships

Additionally, it can provide real-time analysis, forecasting, and reporting. Other processes that manufacturing businesses can improve using ERP are inventory and production. An enterprise resource planning software integrates its core functions and helps businesses improve delivery timelines and overall quality. This is the main reason why many businesses switch from standalone or custom software to ERP.

How Does the ERP System Work?

An ERP system takes over all the operational functions of your manufacturing business and integrates all the components of it. An ERP system has many inbuilt modules that individually handle these processes. Every module focuses on one specific part of your business. For example, the accounting module of ERP automates basic accounting and invoicing. The integration allows the company to maintain a smooth flow of data and collect the entire information in a centralized system. It becomes especially useful during the decision-making process when you require a complete bottom line of the data. You can also make use of ERP software to create workflows and streamline the functioning of your manufacturing business.

What are the uses of ERP System?

ERP systems are complete software solutions that streamline many aspects of your manufacturing business operations. Here are the main areas that an ERP system streamlines:

1. Production: This software can take control of your entire production process, from raw material to end product. It can help you in scheduling, planning and managing different parts of the supply chain. You can rely on the ERP system for the efficient usage of resources and timely delivery of products.

2. Planning: The ERP system also provides an overall planning tool. You can find the main use of ERP software in effectively planning, forecasting, and producing your offering. It can help you project your future needs and plan accordingly. This will help you make sure you are completely planned and prepared.

3. Purchase: This system also improves your procurement process by automating many parts of your purchasing. You can automate many tasks such as vendor selection, purchase order creation, and invoice processing. An integrated software will also let you track supplier performance.

4. Sales: An ERP system can take over your entire sales process, from lead generation to order fulfilment. It can track customer interactions, manage orders and give you further insights based on that. This can help you improve your overall sales.

5. Inventory: ERP systems also provide the tool to maintain your inventory. It can show you real-time inventory levels. This helps you avoid stockouts and overstocks. With this, you can not only keep track of your inventory but you can also manage warehouse operations.

7 Reasons Why ERP is Important for Businesses

An ERP system helps digitize your management process and ease the work of business. But it doesn't end there. There are many reasons which make enterprise resource planning software an important requirement for your manufacturing business. Here are the key reasons that increase the importance of ERP systems for your business.

1. Cost Optimization

An ERP system brings together many of your company's systems that may be all over right now. This system includes everything from product development and supply chain management to information technology (IT) support and management. When one system becomes your go-to software for all the operations, it also reduces your costs. This is one of the key importance of ERP systems in management. Plus, you will not have to train different users on different systems. Instead, you can train all operational workers on the same system/ This will help you save money and time.

2. Customer Relationships

Maintaining good customer relationships is the most important part of running a business. It mostly becomes the most challenging part for businesses to deal with. Many times, employees are unable to dedicate enough time to customer satisfaction. This can happen when they are busy with other work. With the help of ERP systems, the team can automate repetitive tasks and concentrate on customer satisfaction.

3. Business Intelligence

Your analytics and reporting will also benefit from having a centralized system. This system will collect information for you and create a centralized database. This becomes an excellent business intelligence tool, which you can use to handle everything. ERP applications make it easier and faster for your team to create reports. With ERP, the research and compilation will take only a few minutes, instead of weeks.

4. Improved Interaction

A long hierarchy system in an organization affects the smooth flow of communication. Usually, employees use email for communication. However, fast communication becomes difficult using email for employees who are working on operations. An ERP system can provide communication tools like group chats, file sharing, and delegating tasks. They can improve integrations and help oversee projects and other activities easily.

5. Resource Management

ERP provides insight into every aspect of production. With this, users can improve capacity by maximizing production programs, labour, and equipment. It also manages your adjusted assets and Bill of Material (BOM). This helps users create and edit BOMs and keep track of previous changes with this application. A good ERP system makes scheduling equipment maintenance easier. This reduces unexpected downtime and improves endurance and supply chain connections.

6. Decision Making

ERP software provides flexibility and mobility. It automatically collects data from multiple departments into a single platform. This becomes important for making decisions regarding software investments. Modern ERP solutions tap on a centralized digital platform.

7. Regulations & Safety

Using ERP, it also becomes easier to sync back-office operations and manufacturing industry regulations. Most ERP systems providers keep an eye on changes in regulations and compliance. They do it to continually update their features to help you meet the new requirements. Software for ERP makes the processing of data easier and internal processes more efficient. It can also improve security by including firewall systems and restricted data access. System administrators are also able to control and monitor your software's security when multiple processes are integrated into a unified system.

Key Benefits of Implementing ERP Systems

There are many reasons to believe that every business should have an ERP management system to help them with operations. Here are the key benefits of implementing an ERP system in your business:

- Increase efficiency: To handle each component of a manufacturing business, you will need a separate tool. As a result of this, you will struggle with handling various software and application failures. An enterprise resource planning software will help you in this situation. It can provide a single, highly streamlined and integration-focused cloud-based software, which can handle multi-channel information, and increase efficiency.

- Reduce costs: If you are handling your operations manually, the operational costs could be very high. You will also have to increase the manpower as your company grows. This can be a big concern for businesses, especially those in the growth phase. In this situation, an ERP system can prove to be a good alternative. Another use of an ERP management system is to automate tasks, reducing the need for manpower. This will ultimately reduce your costs.

- Better Collaboration: ERP systems are centralized and work as a single unit across all departments. This can improve the collaboration between employees from different departments.

Can You Scale Your SME With ERP?

It is important to keep up with the updated technological trends. Maintaining your business with manual and outdated strategies will not help anymore. But an ERP might not be the best choice for an SME.

Why ERP is not right for SMEs

Implementing Enterprise Resource Planning (ERP) systems in the Indian Small and Medium Enterprises (SMEs) manufacturing sector can be challenging for many reasons. Here are some key reasons why ERP might not always be the right fit:

1. High Cost: ERP systems are expensive to implement. They need a lot of initial investment in software, hardware, and training. Many SMEs in India have a tight budget, making it difficult to allocate resources for such an expensive system.

2. Customization Issues: ERP systems are complex and may require a lot of customization to fit the specific needs of an SME. This customization can be costly and time-consuming. It also requires specialized consultants, which many SMEs in India cannot afford.

3. IT Challenges: SMEs may not have the in-house IT expertise necessary to implement and maintain an ERP system. Hiring external experts or training staff can be an additional financial burden.

4. Resistance to Change: Implementing an ERP system requires changes in existing business processes and workflows. There can be resistance from employees who are used to the current ways of working, leading to challenges in adoption and utilization.

5. Integration Issues: Many Indian SMEs use a mix of custom software and manual processes. Integrating these with an ERP system can be challenging and may require additional time and resources.

6. Data Migration: Moving data from existing systems to a new ERP system can be complex and risky. There is a risk of data loss or corruption. Especially if the existing data is not well-organized or standardized.

7. Scalability Issues: While ERP systems are designed to be scalable, the initial setup might not be aligned with the growth trajectory of an SME. This could lead to additional costs and system reconfiguration as the business grows.

8. ROI Uncertainty: The benefits of implementing an ERP system may not be immediately visible. SMEs might find it difficult to justify the investment without a clear and quick ROI, especially if the business operates with thin profit margins.

9. Regulatory & Compliance Issues: Adapting an ERP system to comply with local regulations and standards can be challenging. The effort and resources required to make sure compliance may make it difficult for SMEs to adopt ERP systems.

These challenges do not mean that ERP systems are completely unsuitable for Indian SME manufacturers. But, they highlight the need for systems specifically designed with the needs of SMEs in mind. You will need something like ERP software that can provide advanced functionality. TranZact can help you manage all the functionalities of an ERP in a single software. TranZact is made keeping Indian SME Manufacturing companies in mind. You can view real-time inventory, quotations, and production data to maximize your company's productivity. It can also help you cut costs, improve efficiency, and simplify complex operations. TranZact is a one-stop solution for all your operational challenges. Its many features make it the best software for small businesses.

FAQs on Why ERP Is Important

1. Why is ERP important for business?

Maintaining smooth operations is very important for a business. An ERP keeps a complete record of business and makes sure different business management applications work together, seamlessly. It helps you collect, store, and analyze data from your business operations in a single centralized location. This makes the ERP system a must-have tool for businesses.

2. What is an ERP software system?

An ERP software system helps companies manage their day-to-day activities. It involves manufacturing, financials, supply chain management, accounting, procurement, project management, customer relationship management, and supply chain management etc.

3. What is the most important function of an ERP System?

The most important function of an ERP system is to make the operations of a business accessible so that it becomes easier for businesses to control them. The system helps them to deal with an easy-to-read, centralized database.

4. What are the 5 benefits of ERP System?

The five main benefits of the ERP system are Increased efficiency, reduced costs, easier management, simplified processes, and higher productivity.

5. Why is ERP important in management?

ERP is especially important in management because it improves collaboration, analytics, productivity and customer satisfaction. Moreover, ERP management software helps companies make informed decisions for their day-to-day operations.

6. What are the 5 Components of ERP?

The five components of an ERP system are production, planning, purchase, sales, and inventory. They are all equally important parts of business operations.