The role of ERP in supply chain management is unparalleled for all businesses. Supply chain maintenance is crucial to businesses and fields like the manufacturing industry.

ERP, popularly called Enterprise Resource Planning, optimizes the product cycle activities from processing the raw materials to developing finished goods and reaching out to the customers.

It has been seen that the majority of employee time is consumed in supply chain management and maintenance. And inadequate and improper management can hamper productivity, quality, expenses, loss in profits, and production capacity.

The supply chain is more crucial when manufacturers seek to expand their manufacturing units. Thus, efficient ERP software covers the various aspects of supply chain and business management by providing lucrative outcomes and efficient solutions.

Understanding the role of ERP in supply chain management can deliver value to every aspect of the supply chain. This article will cover various aspects of the role of ERP in supply chain management.

What Is the Role of an ERP System in Supply Chain Management?

Here are the roles of the ERP system in supply chain management (SCM):

1. Demand and Planning

Identifying the quantities of materials, products, and resources, including labor, is a crucial function of SCM.

2. Material Sourcing

ERP plays an important role in procuring materials and identifying suitable suppliers, subcontractors, and distributors across the supply chain.

3. Production Management

An ERP system aids organizations in efficiently executing production schedules by centralizing production-related information. It includes requisitions, purchase orders, and materials replenishment.

4. Delivery Optimization

An ERP system equipped with Distribution Requirements Planning (DRP) capabilities tracks shipments and provides visibility into quantities and item numbers shipped. It also enhances support and shipping coordination, improving delivery speed and reliability.

5. Financial Control

An ERP system with financial capabilities enables organizations to manage negotiated credit limits with supply chain partners effectively.

Key Takeaways

- SCM analyzes the quantity of goods, materials, and supplies, enabling ERP systems to provide automatic demand and supply projections.

- Using an ERP system with Material Requirements Planning (MRP) features, supply chain managers procure materials and identify suppliers, sub-contract manufacturers, and distributors.

- ERP systems execute production plans efficiently related to Supply chain management, requiring overseeing capacities across manufacturing facilities.

- ERP systems with financial capacities ensure payment records and maintain businesses' credit limits.

- ERP enables dynamic distribution planning, inventory control, efficient time management, and real-time restocking.

- ERP enables smarter resource management methods and real-time operations monitoring by facilitating collaboration between businesses and suppliers, minimizing inefficiencies, and increasing visibility.

Benefits of Using ERP in a Supply Chain Management Strategy

The elements of an ERP interconnect to enhance cooperation and productivity by enabling data exchange. Procurement and logistics professionals can optimize production and minimize costs via precise contracts with suppliers, logistics capacity, and consumer demand.

ERP in supply chain management tackles production responsibilities efficiently. Some of the advantages are discussed below -

1. Improves Supply Chain

ERP systems improve supply chain efficiency by simplifying activities and improving transparency, allowing educated choices to minimize costs in production, shipping, and sourcing.

2. Enhanced Data Security

Cloud ERP software provides benefits like specialized data security and accessibility, which enables rapid response on mobile devices with internet access. This enhances logistics and team collaboration.

3. Enhanced Scheduling

ERP solutions combine logistics data and more effective manufacturing schedules, enabling enhanced scheduling and more precise delivery estimates. It increases customer loyalty and the overall customer retention rate of the company.

4. Reduced Inaccuracies

Enhanced supply and demand understanding enables inventory control, reduced expenses, and fewer operational inaccuracies. It leads to greater warehouse space and reduced mistakes during production and supply chain operations.

Identifying the Right ERP to Improve Supply Chain Management

Operating an ERP system can be challenging if the businesses are unaware of the processes and the factors that may affect the supply chain and the company's production management.

Keep the following criteria in mind to identify the right ERP to improve the Supply chain management system -

- It must meet the basic and foundational requirements of the company. It must perform its functions well and must not act as a hindrance to the production.

- The businesses must consider the costs incurred in the ERP system and the costs incurred on the personnel training.

- The user support and the ease of learning about the ERP systems must be kept in mind.

- The industry experience and precision of the ERP provider must be considered.

- Ensure that the ERP systems integrate with the present production and supply chain without incorporating many changes into the system.

- The ERP system must be customizable.

Don't Forget These Factors When Choosing an ERP System

Here are the factors you must consider when choosing an ERP System -

- Ease of Use

ERPs automate manufacturing operations by coordinating the supply chain and providing user-friendly transportation, handling, manufacturing, and accountancy capabilities.

- Costs

Traditional ERP systems were expensive and required high efficiency to derive ROI (return on investment). However, subscription-based cloud ERP integrates operating expenses, provides predictable expenditures, and delivers faster returns.

- Ease of Integration

Unified SCM and ERP systems operate organically on a single platform, cutting expenses and facilitating connectivity. It also reduces the expenses and time spent by businesses on educating their employees.

- Data Model

ERPs and SCMs which employ the same data model ensure data accuracy. It enhances the overall production and supply chain process. It also reduces production hours and synchronizes data.

- Cloud-based ERP Software

Cloud-based applications enable a view of the supply chain as a whole, offering immediate support, remote connectivity, accessibility, successful production processes, and data accessibility.

Implementing Supply Chain Management and ERP Integration

The supply chain can benefit immensely from ERP integration. It allows businesses to scale up, implement complex systems, and enhance functionality. Keep note that -

- Cloud-based ERP systems are highly preferred as they reduce the need for on-premise systems, and eliminate on-site hardware and software. They maintain and amalgamate key resources.

- Cloud-based mechanisms are easy to scale and allow personnel and staff members to access and evaluate the systems remotely with internet access.

- When converting or establishing ERP systems, consider future business development and urgent needs. This is important, especially among multinational companies with multiple languages, foreign currencies, and tax administrations.

- Companies seeking specialist logistics software could incorporate them with enterprise resource planning (ERP) systems and explore future ERP system capabilities like automation and artificial intelligence (AI) forecasting.

Improve Supply Chain Management With TranZact ERP

TranZact ERP solutions are critical to a manufacturing company's growth. They enhance companies' demand, resource allocation, and schedule production capabilities while reducing overhead costs.

- Handle Consumer Demand

TranZact integrates inventory, sales, and purchase functions on a single cloud-based platform. This enables business owners to save time in collaborating with diverse departments. They can strategize better for handling inventory and consumer demands to maximize revenue.

- Integration with Supply Chain

End-to-end supply chain capabilities are integrated into TranZact ERP, and real-time data regarding production, reports, stock, and orders are updated. It allows procurement, planning, and manufacturing divisions to operate from a single source of data.

- Optimizing Business Operations

TranZact ERP software simplifies quotations management, and order processing for diverse currency denominations. All sales and purchase transactions are updated on a single dashboard for ease of management.

- Profitable for Small Sector

TranZact's ERP solutions are designed for small-sector companies and institutions to handle the manufacturing complexities from sourcing raw materials to shipping products to consumers.

TranZact Provides the Best ERP Solutions to Make SCM Easy

TranZact ERP software simplifies manufacturing production and automates inventory and material handling activities. Remote access streamlines the functionality and scalability of the companies by providing modern capabilities and features.

This software also provides a free trial to enable you to test the software before you adopt it for your business.

FAQs on ERP in Supply Chain Management

1. What is an ERP solution?

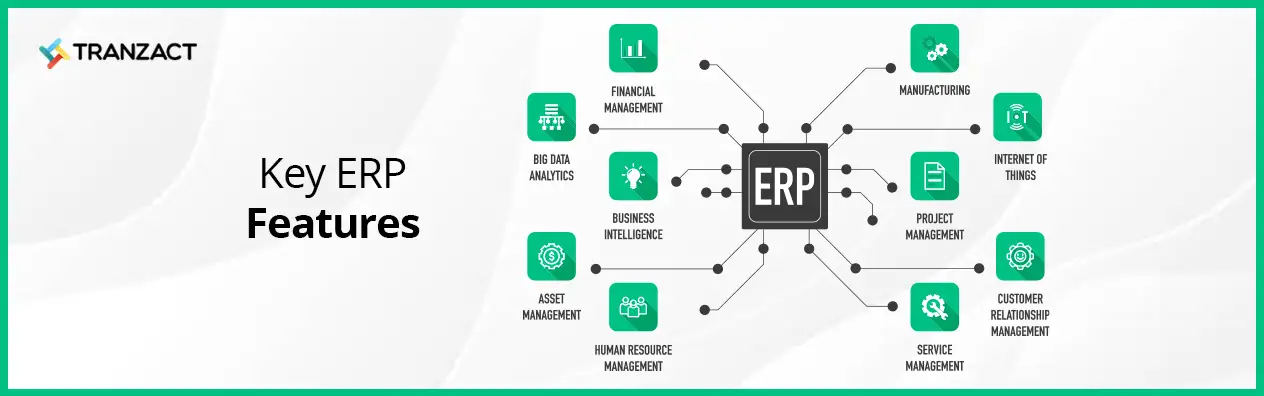

ERP, also called Enterprise Resource Planning (ERP) is a software system based on remote, cloud, hybrid, or physical setup. It automates business functions like procurement, supply chain, manufacturing, finance, production, inventory, and in some cases human resource management.

2. What are the 4 types of ERP?

Four types of ERP systems include Industry-Specific ERPs, Large-Scale ERPs, Intermediate and Flexible ERPs and Box ERPs.

3. Is Supply chain management part of ERP?

ERP systems assist supply chain management (SCM) functions such as procurement, manufacturing, inventory, order management, finance, payroll, and customer relationship management. It supports the enhancement of SCM operations and other business functions by automating core activities.

4. How does the ERP system affect supply chain management?

The ERP system plays a crucial role in improving supply chain management by providing real-time visibility into inventory, streamlining processes, and enhancing communication between different stakeholders.

5. What can ERP do to enhance supply chain management?

ERP systems enhance supply chain management by providing real-time data statistics, lowering costs, and reducing the risk of human mistakes. Enterprise Resource Planning (ERP) systems provide global access to data from their supply chains, support educated decisions, optimize processes, and streamline crucial procedures while eliminating negligence.

6. Who uses ERP solutions?

ERP systems are crucial to small and large-scale businesses in fields like Healthcare, Manufacturing, Retail, Automobile, and others.