Every manufacturing involves several operational tasks that are important to run it. Having a structured operations management is very important to deal with all those tasks. An enterprise resource planning system brings all these tasks together and makes a centralised system for control. An ERP system streamlines your operations management and simplifies all the operational tasks.

In this blog post, we will learn more about the enterprise resource planning system(ERP), its importance and its benefits in operations management. We will also talk about whether ERPs are the right choice for SMEs and how to choose a suitable ERP system for your manufacturing business.

What is ERP in operations management?

At times, the different parts of the operations need to work with one another. Many tasks also require shared functioning. During that time, it becomes challenging for different departments to coordinate with one another. This makes the overall operations and management a difficult task.

An enterprise resource planning software collects data from all the areas of the business and provides a real-time report. It allows businesses to spot trends, find bottlenecks and predict future scenarios. This tool can also automate many tasks in your operations. That will free up your time to focus on business growth.

The importance of enterprise resource planning (ERP) in business operations

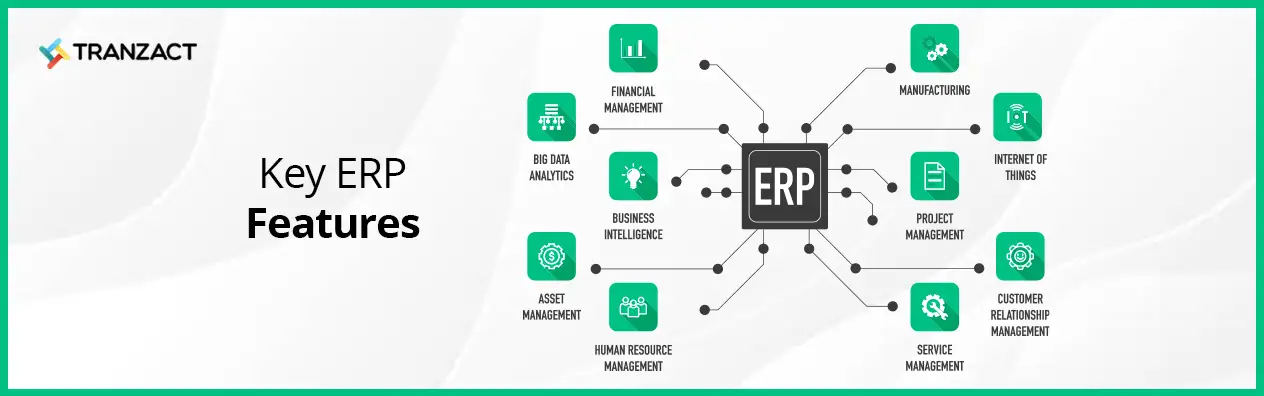

An enterprise resource planning (ERP) system takes control of many parts of your business operations. Here are some reasons that make ERP an important requirement for businesses:

- Integrated Operations: An ERP in operations management combines different parts like planning, procurement, production, sales and inventory in a unified system. This makes sure that everyone in your team is on the same page.

- Task Automation: An enterprise resource planning software can take over some of your routine tasks and automate them.

- Future Scalability One of the most unique features of an ERP system is that it can be upgraded as the business grows.

- Data Analytics: ERP systems collect information from all the parts of your business and provide them in a centralized place.

5 Benefits of Enterprise Resource Planning (ERP) Software

An enterprise resource planning software can improve your operations management in several ways. Here are some of the benefits of ERP software for your operations:

1. Cost Saving:

Enterprise resource planning software reduces the need for human work. They allow you to make the most out of your resources with as little as possible.

For example, a manufacturer can use an ERP to track raw material usage and waste. This data helps the manufacturer adjust its purchasing decisions. This will help them in reducing waste and saving money.

2. Inventory Management:

ERP in operations management provides a real-time view of inventory levels. This can help them avoid overstocking and understocking. It can let businesses make a demand forecast.

This tool is equally important for manufacturers, wholesalers and retailers to maintain their inventory and warehouse.

3. Integrated Information:

What makes ERP in operations management unique is its ability to collect data in a standardized place. It collects data from all the departments and presents the information in an integrated place.

This will remove the data confusion. It will also make sure that everyone is working with the same regularly updated information.

4. Improved Supply Chain:

ERP systems provide visibility into the entire supply chain. This includes everything from suppliers to customers. This is particularly important for businesses that have multiple stages between the initial and final product.

5. Data Security:

ERP systems have many security measures in place to secure sensitive data. It gives business owners the complete control over their data and information. This helps them make sure about the integrity of the information.

Why is There a Need for Alternatives to ERP for SMEs

ERP systems offer complete solutions for manufacturing businesses. But, they may not be the best fit for Small and Medium Enterprises (SMEs), especially in India.

Here are some of the reasons why SMEs look for alternative approaches:

1. Cost-Effectiveness:

ERP in operations management requires a big upfront investment. But, solutions that come in parts allow businesses to only pay for the modules they need. This can significantly reduce the cost of the software that you need. This is especially important for SMEs with limited budgets.

2. Customizability:

You can customize the tool to fit the specific needs of an SME. Small and Medium-sized businesses can choose the modules they need and avoid customization.

3. User-Friendliness:

ERP in operations management can be a bit complex. They might also require IT expertise to implement and maintain. However, solutions that offer customizability are usually more user-friendly and do not require any training.

- Scalability: Small and medium-scale businesses grow quickly. In that case, additional modules can be added to the system.

- Quick ROI: SMEs usually buy only the modules they need. This helps them to manage the cost, especially for businesses operating with thin profit margins.

- Software Implementation: Implementing an ERP system can involve difficult processes that require the help of a professional. There could be additional charges for taking assistance.

- System Maintenance: ERP in operations management also require maintenance to make sure that they work properly. This can include costs for software updates, troubleshooting, and user support.

What are the examples of ERP in inventory management?

Enterprise Resource Planning (ERP) systems are important for inventory management in today's time. They can track inventory levels, orders, sales, and deliveries.

- An example is Oracle's NetSuite. This cloud-based solution is particularly popular among businesses seeking scalability and flexibility.

- One of the most versatile software that can help you with operations is TranZact. TranZact is the easiest software made for Indian Manufacturers that contains only the required modules. No extra cost goes into purchasing the unnecessary modules.

- Lastly, Microsoft Dynamics 365 Supply Chain Management is another popular choice in inventory management. It helps businesses optimise their supply chains and reduce operational costs.

These are just a few examples of how these tools are revolutionizing ERP in inventory management.

What to do before choosing an ERP system for operations management?

Here is the step-by-step guide for you on what to do before choosing an ERP system for operation management:

1. First, you will have to find out the needs of your business. Try to understand how an ERP system can help you.

2. Find out how much you can invest in an ERP system and the additional charges.

3. Then, look at the vendors to understand the features and benefits of ERP software.

4. You will have to make a training and migration strategy. You will also have to think about implementing ERP in operations management.

Challenges in Implementing ERP

The journey of implementing an ERP system into your manufacturing business can be full of obstacles. They also require some investment in software, and training, which can be a challenge. Customization is the biggest challenge. Many ERP systems are often complex and may not fit the specific needs of a small to medium-scale manufacturing business. You can instead buy software that comes with separate modules.

SMEs might not have the IT expertise required for an ERP system. For this, they may need to hire experts to help in the implementation of ERP in operations management. They might also have to invest in training for their staff. You might have to make changes in existing business processes to set in the ERP. The employees will also have to change the way they work. Integration and data migration can also become challenging.

Future Trends of ERP in Operations Management

Technology is progressing every second. With that, all software, tools and applications are advancing too. ERP in operations management will also see some upgrades in the future. Currently, more and more businesses are adopting cloud-based ERP solutions. This is because every manufacturing business wants scalability and cost-effectiveness.

Soon, AI and Machine Learning integration can be a big thing in ERP. It can help people automate many tasks. The Internet of Things (IoT) is also improving operations through real-time data collection. Lastly, as ERP systems centralize sensitive data, there will also be some focus on cybersecurity measures. To learn more read this blog - the future trends in ERP.

Control Manufacturing Operations with TranZact

An ERP tool is not just a tool but a strategic asset. It improves processes, and efficiency, and drives business growth. There could also be situations where you do not need the complete ERP software but only some components of it. In that case, you should look into tools that come in separate modules. TranZact is one such tool that comes with many modules that can be integrated. It can help you navigate through the complexities of Operations Management.

FAQ

1. What is ERP in operations management?

ERP in Operations Management is a software system that integrates all aspects of a company’s operations. This includes finance, human resources, manufacturing, supply chain management, etc. It helps manufacturing businesses manage all their operations.

2. What factors are required in operation for ERP to be successful?

For ERP to be successful in operation, a business should have:

- Understanding of Goals

- Good implementation team

- Commitment to management

- Data Accuracy

- A Suitable System

3. What are the 5 components of ERP?

The five main components of an ERP system are Finance, Human Resources, Manufacturing and Logistics, Supply Chain Management, and Customer Relationship Management.

4. What is an ERP system implementation?

It is the process of implementing the process of adopting an ERP system. It also involves integrating the operations and business processes. The main parts of it are planning, customizing, and deploying the ERP system throughout the business.

5. What are the 7 stages of ERP implementation?

The seven stages of ERP implementation are: Discovery and Planning, Design, Development, Testing, Deployment, Ongoing Support and Improve.

6. What are the 5 main benefits of ERP software in operations management?

The five main benefits of ERP software in operations management are Integrated Business Processes, Real-time Information, Improved Efficiency, Better Customer Service and Scalability.