In the daily operations of Indian SME manufacturers, a well-managed supply chain is important. However, it is challenging to achieve. Many small and medium-sized businesses face issues like inconsistent raw material supplies, delayed deliveries, and higher costs due to gaps in their supply chain management.

These problems can lead to difficulties in meeting customer demands and maintaining steady production.

This blog post will explain what a supply chain is, its different models, highlight common challenges faced by Indian SME manufacturers, and offer practical tips to help improve supply chain efficiency and reduce costs.

What Is a Supply Chain?

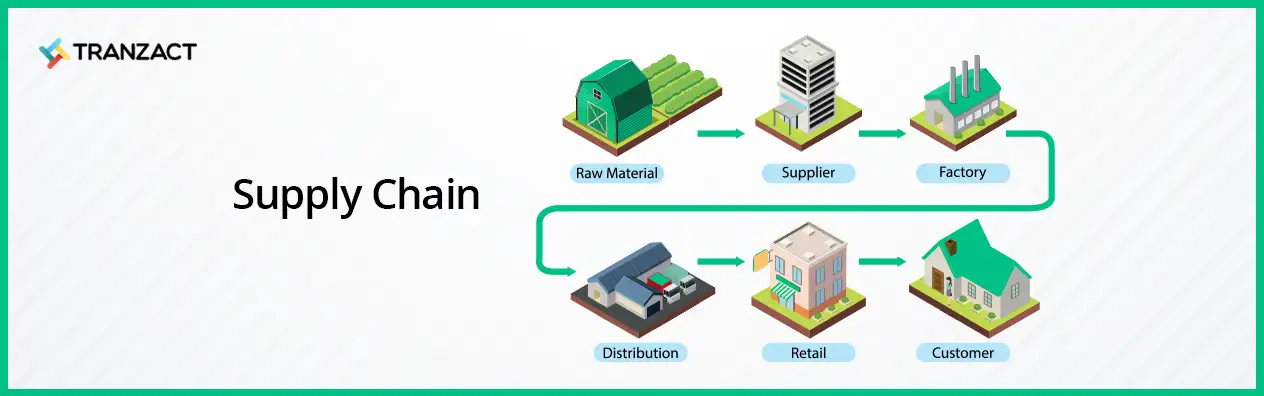

A supply chain process is a system that involves many processes working together to deliver products to consumers. It includes all the steps from the creation of a product to its delivery. At its core, logistics and supply chain management involves many stages. It starts with buying raw materials, then manufacturing,distribution, and reaching the customer.

Each step involves different players, like:

- Suppliers

- Manufacturers

- Distributors

- Retailers

All of them work together to make sure products are available when and wherever needed. The supply chain process can be long, stretching across the globe, or short and local. They can be simple or difficult, depending on the product and the industry. Nowadays, technology plays an important role in managing and improving supply chains. It makes sure of efficiency and reduces costs.

Read How to Start a Small-Scale Manufacturing Business in India

Understanding a Supply Chain

A supply chain is very important in our economy. Here's why:

1. Efficient Sourcing: Supply chains simplify the sourcing of raw materials. It makes sure that companies receive them quickly and in perfect quantities. As a result, businesses can meet consumer demand efficiently and maintain product quality.

2. Smooth Distribution: A good supply chain makes sure products move smoothly from factories to stores or customers. This smooth and well-organized distribution process reduces delays in order fulfillment.

3. Consumer Satisfaction: A well-managed supply chain plays an important role in maintaining consistent product availability. When products are easily available to customers, it meet their demands and keeps them happy.

4. Cost Management: Efficient supply chains help companies control expenses throughout the production and distribution processes. Businesses can make sure that their products remain affordable. It is done by improving operations and reducing waste.

5. Global Reach: Supply chains help businesses to source materials and distribute products on a global scale. This helps open up new markets and opportunities. It allows companies to reach many customer bases and expand their presence.

Read Top 10 Digital Tools for Digitising Your Manufacturing Business.

Steps in Supply Chain

The step in a supply chain functions involves a series of actions that products go through. These steps make sure the products reach consumers efficiently:

1. Plan: Determine what to produce and how much.

2. Sourcing: Find suppliers for raw materials or products.

3. Manufacturing: Manufacture the products.

4. Delivering: Transport products to distribution centers.

5. Storing: Store the products until needed.

6. Marketing: Learn to market and sell products to customers.

7. Handling Returns: Understand if there is any return for the product.

8. Recycling/Disposal: Handle the disposal or recycling of the product.

Supply Chain Models

Supply chain models helps businesses easily manage moving products from suppliers to consumers. These models are available in many formats. Here are some of the types of supply chain models:

1. Lean Supply Chain: Lean supply chain is a model focused on efficiency and waste reduction. It achieves this by reducing extra inventory, thus cutting storage and holding costs. It works best for businesses with steady and predictable demand.

2. Agile Supply Chain: The agile supply chain model prioritizes flexibility and adaptability. It allows businesses to respond quickly to unpredictable changes in market demand or emerging trends. This model suits industries where demand can change significantly.

3. Just-in-Time (JIT): The just-in-time supply chain delivers materials or products accurately when needed. It reduces the need for wide warehousing and storage. It is commonly used in manufacturing and automotive industries.

4. Vendor-Managed Inventory (VMI): VMI model lets suppliers take responsibility for monitoring and restocking the buyer's inventory. This reduces the buyer's workload and makes sure that they never run out of important items. It leads to more efficient supply chain operations.

5. Push vs. Pull Models: The push model involves predicting demand and pushing products into the market accordingly. In contrast, the pull model responds directly to actual customer demand. Combining elements of both models can help grow inventory management.

Read The Future of Manufacturing: Predictions for the Next Decade.

Supply Chain Challenges

Businesses can find handling supply chains tricky. Below are five common supply chain challenges they often have. These challenges impact everything from keeping customers happy to managing costs effectively.

1. Demand Fluctuations

Customer demands can go up and down, making it hard to predict. This can create a problem where a business either has too much stock or too little stock. Finding the right balance is important to satisfy customers without wasting resources. It is one of the important functions of supply chain.

2. Supplier Reliability

Suppliers who don't deliver on time can spoil the whole process. Late order fulfillment can make customers unhappy. Having trust in dependable suppliers and backup plans is important for a smooth supply chain.

3. Logistics and Transportation

Getting products from one place to another can become complicated and expensive. Slow or inefficient transportation can lead to delays. Smart planning and better routes can help reduce these problems and make sure an optimized supply chain.

4. Inventory Management

Not handling stock well can mean extra expenses. Running out of things to sell means lost sales. Having too much stock ties up money. Using good inventory systems maintains balance. It makes sure that the right products are available when needed.

5. Natural Disasters

Supply chains that stretch across the world can face many risks. Natural disasters, such as earthquakes, hurricanes, floods, or wildfires, can stop the flow. Protecting against these risks is one of the importance of supply chain operations.

Supply Chain Management Best Practices

Supply Chain best practices are expert tips for easy supply chain management process in businesses. These practices help companies deliver products smoothly and keep their customers happy. Here are some of the supply chain management best practices:

- Keep open and clear communication with suppliers and partners to make sure everyone is on the same page.

- Use data and trends to predict customer demand accurately, reducing the risk of overstocking or stockouts.

- Regularly assess and adjust inventory levels to reduce costs while meeting customer needs.

- Build strong relationships with suppliers for reliability and flexibility in the supply chain.

- Implement modern software and tools to simplify processes and improve visibility.

- Regularly analyze the importance of supply chain management operations. It adapts to changing market conditions.

- Identify and plan for potential disruptions, from natural disasters to market fluctuations.

- Use eco-friendly practices to reduce environmental impact and meet consumer demands.

Supply Chain Management vs. Logistics Management

Supply Chain Management and Logistics Management involve managing the movement of goods. They look like they are related, but in reality, they are different from each other. Understanding the key difference between logistics and supply chain management is important for easy business operations.

Supply Chain Management involves overseeing the entire process. From sourcing raw materials to delivering the final product to customers. It focuses on coordination, planning, and improvement across the supply chain network.

On the other hand, Logistics Management is a subset of supply chain management. It focuses specifically on the movement and storage of goods. Logistics Management focuses on shipping, distributing, and storing goods.

Take Control of Your Supply Chain with TranZact

A well-managed supply chain is the heartbeat of any successful business. It makes sure of easy operations and satisfied customers. TranZact improves this important link for businesses, promoting efficiency, cost-effectiveness, and growth.

Read How TranZact Can Digitise Your Manufacturing Business: A Comprehensive Guide

FAQs on Supply Chain

1. Does the supply chain cause deflation?

No, the supply chain itself doesn't cause deflation. Various economic factors can influence deflation. It leads to a drop in overall prices.

2. What is the flow of manufacturing cost?

The flow of manufacturing costs starts with raw materials. It adds labor and other expenses during production. It ends with the final product's cost.

3. What is supply chain management?

Supply chain management is about organizing how products are made, moved, and delivered. It makes sure that everything runs smoothly from suppliers to customers.

4. How does a supply chain affect sustainability?

Supply chains can impact sustainability by promoting eco-friendly practices. These can reduce waste and make sure of responsible sourcing of materials.

5. How does inflation affect supply chains?

Inflation can affect supply chains by increasing the costs of raw materials, transportation, and labor. It leads to higher prices for goods.

6. What's the difference between value chains and supply chains?

Think of a value chain as the journey of creating something, step by step. A supply chain is the bigger picture, involving all the steps to get a product to customers.

- Value chains focus on creating and delivering value to customers.

- Supply chains mainly deal with the movement and management of products and materials.