Engineering companies often face various problems with effective manufacturing management. With the right ERP software for engineering companies, you can easily streamline such processes. ERP systems for engineers provide various features that streamline project management and improve team collaboration.

In this blog post, you will learn the top features of ERP systems for engineering companies. You will also know their importance and how it’s beneficial for engineering firms.

What Is ERP Software For Engineering Companies?

Engineering is a complex process and its operations are even more complex to handle for engineering companies. Engineering ERP software is a system specially designed for engineering and manufacturing businesses to help with project planning, good manufacturing practices, and team collaboration.

The software supports the operations at all stages including inventory management, production planning, create a BOM (bill of material), etc. The effective ERP solution for engineers also allows the integration of CAD (computer-aid design) software. With the help of ERP for engineering and CAD, you can easily generate the list of items needed in the manufacturing process.

How Does Engineering ERP Software Work?

The engineering companies manage most of their important tasks with manufacturing ERP software. The ERP for engineering industry has many functionalities, including the design, production, and construction of new products. All these operations come with solutions that execute complex projects and maintain the cost of production and pricing.

Here, ERP helps them to manage operations easily. With the right ERP software for engineering companies, you can integrate all the departments and automate the process. It also helps reduce errors in the complex design and carry out resource and inventory management while reducing the cost.

Why Do Engineers Need An ERP?

The main work of an engineer is to build or create something. But for engineering companies, other factors like handling financial accounts, effective utilization of resources, and production processes are also important. The ERP software for engineering companies provides automating those.

The best ERP software for small businesses also automates the creation of BOM (bill of materials), accounting process, and supply chain management. These features help engineers to simplify their operations. It lets them focus on the design process and products.

Benefits Of Engineering ERP Software

ERP software provides engineers with flexibility in automating production scheduling and accounting processes. These features help you focus on your core business and improve productivity. Here are some quick benefits of ERP system for engineering companies.

1. Automated Production

The engineering ERP software automates the production processes of your business. This includes the production process, purchase orders, sales orders, inventory, etc. This helps save lots of time in the workforce and improves productivity. Engineering companies also have to keep track of their productions. If the process is automated, you can be carefree and track the process.

2. Financial Visibility

The ERP system for engineering companies helps you with production costing, and invoice generation throughout the process. The ERPs are also designated to automatically generate types of BOM, invoices, e-way bills and invoices. You can use an ERP to increase accuracy with automated revenue collection and monitor numerous projects at the same time.

3. Increased Profitability

ERP implementation in engineering firms allows you to analyze the time and expenses of the project. ERP software for engineering companies helps with budget monitoring and KPIs (Key performance indicators) in real-time. All these data allow you to optimize the production line and make improvements to increase profitability.

4. Historical Data

The best ERP software for manufacturers in engineering companies will provide integrated data from all the departments. The data helps you plan your production, predict demand, and make overall decisions. You can easily access valuable information using a single software and increase productivity.

5. Resource Planning

The right ERP software for engineering companies helps you with effective inventory management and resource planning. You can monitor the inventory used in manufacturing and get visibility of staff skills and activities as well. ERP software will assign the right resources to the right project and make the most out of your team’s time.

6. Improve Working

With the advanced ERP for engineering firms, you can easily automate manual tasks through the. ERP software for engineering companies lets you manage and track the data accurately. It also integrates the working of various departments. It makes it easy to share files and improves the working process within your engineering units.

7. Client Satisfaction

When your production process is streamlined, you will be able to produce the final product always in time. This can improve your delivery timeline and improve client satisfaction. ERP allows communication with the customer collaboration and real-time project reporting.

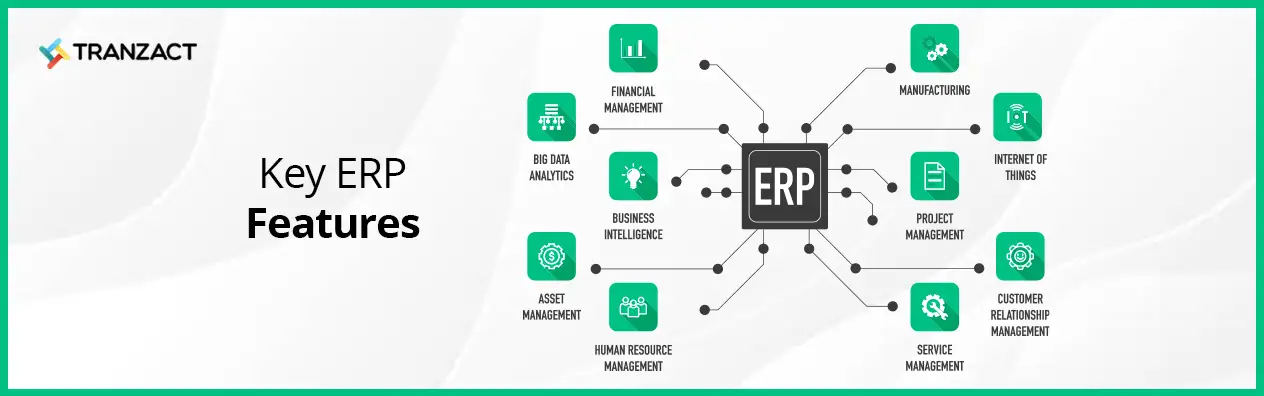

Key Features Of Engineering ERP Software

ERP is an important part of a manufacturing business that helps in back office operations easily. Here are the key features of ERP software for engineering companies that allow you to manage your material requirements and production schedule.

1. Inventory Management

The biggest problem that any engineering company faces is maintaining ideal inventory levels for production. The ERP software for engineering companies can use the material requirement planning (MRP) tool to calculate the raw material. It will allow you to track the raw materials needed for production and analyze sales demand, lead time, and resource capacity.

2. Supply Chain Management

The MRP functionality of the ERP system allows you end-to-end interaction with the supplier and helps in purchasing raw materials. This helps you keep track of incoming orders. With this info, you can send reminders for the required raw material. This streamlines the supply chain on both sides.

3. Production Planning

For production planning in engineering companies, bills of material (BOM) are very important. ERP software for engineering companies provides the feature of BOM and helps create the framework of finished goods. It also outlines the components and determines material requirements.

4. Production Management

The best ERP software for small business can help you organize the production process. This includes releasing the production order and issuing raw materials. It lets you track the performance of your labour and machine runtime. It also lets you schedule your production process etc.

5. Reporting And Analytics

ERP software in engineering can be integrated into different aspects of your business. You can access all the data at a place and make a report to analyze and identify areas for improvement. The ERP software for engineering companies comes with a standard pre-built report that lets you make an analysis.

How To Choose Right Engineering ERP Software For Your Business?

When selecting the right ERP software for engineering industry, you need to determine your needs first. These may include strategic planning, risk management, finance and accounting, and many more. Once you are ready with the initial requirement, shortlist the vendor by analyzing their reputation and services.

After finalizing your ideal ERP software for engineering companies, ask for a demo to analyze its functionality. Prepare an RFP (request of proposal) to the company while maintaining all your needs. The final step is to install the ERP system in your engineering company as per your RFP.

Choose TranZact To Manage ERP At Your Engineering Company

TranZact and ERP At Your Engineering Company

ERP plays an important role in simplifying tasks and operations in engineering companies. ERP software for engineering companies helps you automate production schedules, inventory management, invoice generation, and many more. To automate your material requirement planning, creating BOM, and many other valuable tasks, TranZact is an ideal choice. It’s not an ERP but provides complete visibility of supply chain and inventory tracking.

Use TranZact to easily improve your invoicing and manufacturing processes and streamline the supply chain.

FAQs

1. What is ERP in Engineering?

ERP in engineering is a software solution that allows engineering companies to automate their inventory tracking, manage accounting, and streamline the production line.

2. Do Engineering companies use ERP software?

Yes, engineering companies do use ERP software to analyze their project costing, automate accounting, optimize resource allocation, and enhance operational efficiency.

3. What are the types of ERP software used by engineering companies?

Engineering companies use various types of ERP software, among which the most frequently used ERP types are as follows;

- Project Management ERP

- Resource Planning ERP

- Finance Management ERP

- Supply Chain Management ERP

- Quality Improvement ERP

- Document Management ERP

- Report and Analysis ERP

4. In what ways can ERP elevate the day-to-day operations of engineering companies?

ERP improves the day-to-day operations of engineering companies by solving the following issues;

- Handles the projects

- Monitors inventory

- Optimum resources utilisation

- Ensures quality standards

- Streamline communication

- Automate workflow

- Decision Making

5. Can ERP play a role in assisting engineering companies in maintaining compliance with industry standards?

Yes, ERP plays an important role in assisting engineering companies to maintain compliance with industry-standard in the following ways:

- Mitigating risks

- Provide safety guidance.

- Following industry regulations

- Help to maintain quality

6. Does ERP contribute to cost control in engineering projects?

Yes, ERP contributes to cost control in engineering projects in the following ways:

- Automating the billing and invoicing

- Reducing the risk of human errors

- Monitoring the project costFreeing the staff for more valuable tasks