Plastic is one of the most used materials in everyday life, and SMEs involved in polymers and additives manufacturing need to fulfil the vast market demand. The plastic industry is one of the biggest sectors of all industries due to the usage of materials. ERP for plastic industry plays an important role in fulfilling the increasing demand by following sustainable production, effective inventory management, improving the accounting process, and many more.

Choosing cloud ERP software can automate your full operations, such as production scheduling, inventory tracking, supply chain management, invoice and bill creation, and more. In this blog post, we will learn about the best ERP software for the plastic manufacturing industry. We will also understand how it can help you improve your overall business operations.

ERP For Plastic Industry

ERP for plastic industry is an effective solution to automate production. Using ERP, SMEs can easily track their inventory, manage their production, improve their supply chain, and conduct accurate accounting processes. ERP system for plastic industry allows SMEs to stay updated with the industry standards and all the laws of the local and central government.

Read What is ERP Software: Functions, Solutions, and Use Cases.

Need Of ERP For The Plastic Manufacturing Industry

Plastic manufacturers often produce polymer materials for several industries, including automobile companies, household items manufacturers, and electrical and electronic businesses. These manufacturing businesses often have a huge demand for plastics and plastic components for their products. Plastic manufacturing SMEs are always under pressure to meet deadlines while maintaining sustainable production, minimizing errors, and tracking ongoing performance.

With plastic manufacturing ERP software, SME businesses can follow all the compliance related to environmental regulations and boost sustainable plastic production. They get real-time updates on different manufacturing activities like production performance, workflow, market demand, and inventory, helping them to make informed decisions.

ERP for plastic manufacturing helps them improve every factor in production, from designing to CRM (Customer Relationship Management). Implementing the right ERP system in your business automates your manufacturing operations, helps you create effective production planning, and improves the accounting process and resource management.

What Are The Major Challenges Of The Plastic Industry?

Here are some major challenges of the plastic industry.

- Maintain production efficiency while considering market demand.

- Setting up large manufacturing units as per government rules and regulations.

- Produce error-free products while maintaining quality when the demand for the product is high.

- Sometimes companies have to choose alternative materials to reduce their environmental impact, which is costly.

- Increasing competition needs to be tackled with improved business operations and CRM to stay relevant in the industry.

Know 8 ERP Implementation Challenges and Risks.

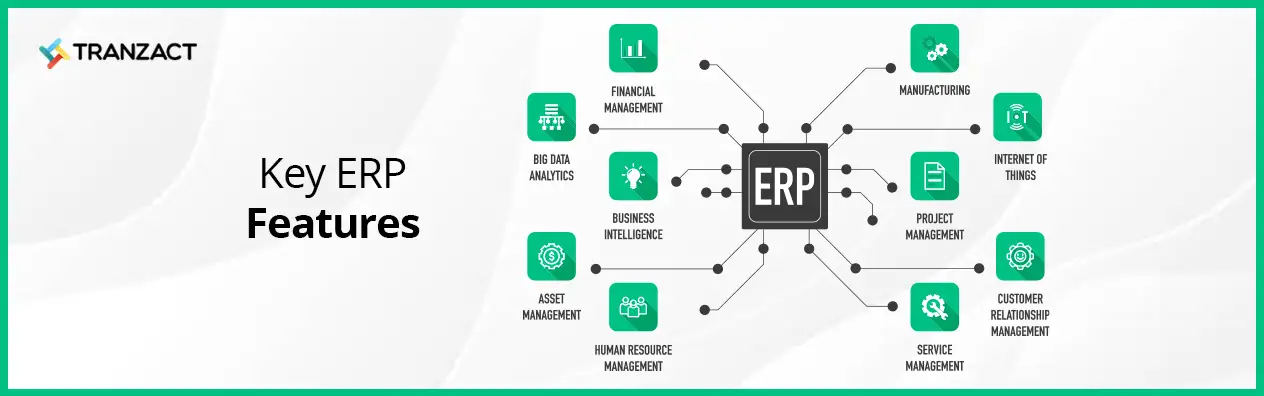

Key Features Of ERP Software For Plastic Industry

Plastic manufacturers need the best plastic ERP software that includes effective features to improve production and maintain product quality.

Here are the key features of modern ERP software you should look for:

1. Production Management

The ERP for plastic industry should have a production management system to automate manufacturing operations. This includes production scheduling, that helps with assigning specific tasks to the team. The software should have a centralized dashboard and a common place to collaborate with your suppliers, engineering team, stakeholders, and account department for effective planning and management.

2. Quality Control

The best ERP will help you make a list of quality measures that you can use to maintain the quality of the finished goods. Your plastic ERP software should keep you updated with regulatory compliance when new laws or information appears in your industry so that you can adapt to the required changes without delays.

3. Requisition And Approval System

Creating a multi-level BOM (Bill Of Materials), creating a purchase requisition, and getting it approved by the higher authority and accounting department can be time-consuming. The plastic manufacturing ERP includes a requisition and approval system, which helps with the easy sharing of bills, invoices, and other papers and speeds up the approval process. This will help with quick procurement of raw materials, execute your production process as per plan, and improve CRM.

4. Batch Inventory Management

Inventory management is one of the most important parts for plastic manufacturers to maintain sufficient space for raw materials, semi-finished products, and finished goods. The cloud ERP software may contain batch inventory management software that allows integration of a barcode system or RFID (Radio Frequency Identification) system. Using such technology in your plastic manufacturing business, you can track your big lots in less time, categorize them based on their chemical and physical properties, and monitor their performance.

5. Scrap Management

The scrap management software helps you monitor the input of raw materials and the waste produced during production. It helps to reduce the scrap through proper production planning and creates a waste management system that reduces the environmental impact and improves the revenue model.

6. Multiple Warehouse Management

The best cloud-based ERP software for SMEs involved in plastic manufacturing helps you manage multiple warehouses in a place. The system allows you to locate multiple warehouses using a centralized dashboard. You can set min/max levels on inventories. You can also easily arrange the inventory based on their categories, monitor the performance of your stocks, and manage space for the raw materials.

7. Documentation Storage

The documentation functionality of ERP helps to maintain the valuable papers that are used during the production process. This helps in keeping a record of all the communication with the stakeholders, like emails for future reference. It also speeds up the creation and maintenance of types of BOM, sales and purchase orders, and more. You can also track supplier and buyer needs at a place through a centralized dashboard.

8. Order Processing And Automation

The advanced ERP software allows you to set the prices of all the parts and materials required for plastic manufacturing. This helps you to get alerts of the changing gross margins on the raw materials and allows you to make informed decisions in purchase orders. You can also automate the invoice and delivery notes and send them electronically to your suppliers to save time and resources.

Benefits Of ERP Software In Plastic Manufacturing Industry

Selecting the right ERP software for your plastic manufacturing business can help you improve your production planning. It helps improve supply chain management and inventory management with other benefits, which we have discussed below.

- Precise Production Scheduling: Makes schedules for plastic manufacturing processes, reducing downtime and optimizing output.

- Material Waste Reduction: Tracks material usage and reduces waste, improves profitability.

- Regulatory Compliance: Helps to adhere to industry-specific standards, reducing risks of non-compliance.

- Batch Traceability: Monitors production batches for better quality control and recall management.

- Inventory Management: Manages raw materials like resins and polymers effectively, making sure of timely availability.

- Tooling Management: Optimizes the use of moulds and tooling to extend their lifecycle and reduce costs.

Selecting the right ERP software for plastic injection moulding is difficult.

Read the Advantages and Disadvantages of ERP.

Top ERP Solutions For Plastic Manufacturing Industry

The ideal ERP software for the plastic manufacturing industry is one that helps you forecast customer demand and plan the production to execute it without difficulty. The ERP for plastic industry must offer customizable options and follow the required industry standards. Let’s see the list of top ERP solutions for your plastic manufacturing businesses.

1. TranZact

TranZact offers effective ERP modules for the plastic industry to simplify manufacturing operations. Its integrated web-based inventory management software helps you automate stock updates, reports stock valuation history and aging, and provides automatic alerts and reminders for production planning. TranZact also helps you meet industry-specific standards by properly planning sales and purchases. It is an easy-to-use ERP solution that can improve your accounting process through real-time reports and data imports.

2. Odoo

Odoo provides a number of ERP modules to manage your plastic manufacturing operations. You can track your multiple warehouses, inventory, expenses, and more. You can also manage human resources, product lifecycle tenders, agreements, customer queries, and more with Odoo.

3. Oracle NetSuite

Oracle NetSuite ERP solution created for SMEs and large businesses. It helps you simplify the accounting process and manage proper documentation. The software is also known to improve the relationship with customers and vendors through its effective CRM.

Factors To Consider When Choosing An ERP For Plastic Manufacturing

When selecting plastic industry ERP for your manufacturing business, prioritize cloud-based solutions that meet specific industry needs like MRP, batch tracking, and quality management. Make sure it provides scalability, IoT integration, regulatory compliance, and good security. Evaluate vendor reputation, customer support, and ease of implementation. Choose software with customizable modules and advanced real-time reporting to support business growth and adaptability.

Case Studies And Success Stories

Taurus Packaging Private Limited is the leading brand in providing packages of goods to several businesses. The industries it serves are home and personal care, food and beverage, healthcare and pharmaceutical, dairy, and telecom markets in India. Taurus is known to provide premium printing packaging solutions, which allow them to deal with plastic manufacturing and materials.

A few years back, the company was facing challenges in improving CRM and increasing profitability. Chetan Jain, the Founder and Managing Director of the company, came to TranZact in the hope of getting the best ERP for plastic industry, which can improve the quality of products and increase sales. TranZact offers industry-specific modules with integrated ERP software like Tally and Odoo, which improved its operations and smoothened the accounting.

With this initiative, the company was able to improve its customer relationship by 45% while improving product quality. The company is still growing and has shown unbelievable growth in its productivity and increased profitability.

Final Thoughts On The Future Of ERP In The Plastic Manufacturing Industry

From manufacturing furniture, toys, and packaging materials to automobile and construction parts, you can find the use of plastic everywhere. ERP solutions are adapting AI technologies that help you analyze the customer’s behaviour, forecast the market trend, get business alerts in real time, and prevent overstocking.

The integration of IoT (Internet of Things) devices like barcode systems and RFID can automate the record-keeping process and inventory management. Plastic manufacturers can easily access these data for strategic production planning and scheduling. It can help to make data-driven decisions, reduce production costs, and be consistent with order supplies while improving CRM.

Simplify Your Plastic Manufacturing Process With TranZact

Plastic manufacturing is a big industry that faces several challenges and requires advanced technology to manage it. But not every business can afford an ERP, especially SMEs. In a small business, money needs to be used smartly! TranZact provides cloud-based modules of ERP for plastic industry with the latest technology and functionality but at lower prices. It offers 5 modules that are specially designed for Indian SME manufacturers - Sales, Purchase, Inventory, Production and Planning. It digitises all your processes from enquiry to dispatch.

Read ERP vs TranZact: What’s Better for SME Manufacturers?

Choose easy-to-use TranZact now to scale up your plastic manufacturing business with GST compliance and improved operational activities.

FAQs

1. What is ERP software for the plastic manufacturing industry?

ERP software for the plastic manufacturing industry is the solution to automate numerous operations for SMEs in plastic production, such as effective inventory management, real-time demand forecasting, machine maintenance, accounting, and many more.

2. How does ERP software benefit plastic manufacturing companies?

ERP software benefits plastic manufacturing by automating production processes, imrpoving scheduling, quality control, real-time tracking, and accounting, while reducing waste and supporting sustainable practices.

3. How much does plastic ERP software cost?

The plastic ERP software can cost from Rs. 8,00,000 to Rs. 10,00,000 depending on the plan you choose, such as one-time payment or subscription-based. The prices may also differ depending on the modules you have chosen or the type of software, such as cloud-based, on-premises, or hybrid.

4. Can ERP software help with plastic injection moulding processes?

Yes, ERP software can help with the plastic injection moulding process with real-time inventory tracking, managing waste, maximising quality control and improving business operations.

5. How does ERP software improve quality control in plastic manufacturing?

ERP software improves quality control in plastic manufacturing by providing a centralized dashboard to collaborate with the engineering team and design the product with the right dimensions.

6. What factors should be considered when choosing an ERP for plastic manufacturing?

Factors you should consider when choosing an ERP software for plastic manufacturing are:

- Industry-specific modules

- Scalability with growing business

- Third-party integration

- Centralized dashboard

- Real-time reporting and analytics

- Data security features

- Implementation timeline and process

7. What are the key features to look for in an ERP software for plastic manufacturing?

Key features to look for in an ERP software for plastic manufacturing are:

- Production Management

- Quality Control

- Requisition and Approval System

- Batch Inventory Management

- Scrape Management

- Multiple Warehouse Management

- Real-Time Reporting and Analytics

- Documentation and Storage

- Automation of Routine Tasks

8. Is ERP software suitable for small and medium-sized plastic manufacturers?

Yes, some specific ERP software that offers customization features can be suitable for small- and medium-sized plastic manufacturers to help you improve production scheduling and automate manual tasks. But in general, they are expensive for SMEs.

9. What are the deployment options for a plastic ERP system?

The deployment options for a plastic ERP system are:

- On-Premises ERP

- Cloud-Based ERP

- Hybrid Option

- Hosted ERP

10. Does Plastic ERP lead to a reduction of manpower?

Yes, plastic ERP can lead to a reduction in manpower due to the following reasons:

- Automates the routine task

- Reduces the manual coordination and communications

- Reduces errors through manual works

- Better usage of human resources

- Reduces manpower in administrative or accounting department

11. Can ERP software integrate with existing systems in a plastic manufacturing company?

Yes, ERP software integrates with existing systems in plastic manufacturing by using middleware, which acts as a bridge between different types of software and effective data transfer.

12. What are the future trends in ERP software for the plastic manufacturing industry?

The future trends in ERP software for the plastic manufacturing industry include Cloud ERP solutions, which offer greater flexibility and scalability to market change and are cost-effective.