Enterprise Resource Planning (ERP) software helps SME manufacturers with many operational tasks. This includes inventory tracking, meeting deadlines, automating invoicing and billing, and many more tasks. For SME manufacturers, an efficient ERP system for manufacturers handles all the operations and streamlines them.

It is important to find an ERP system that fulfils the specific needs of your manufacturing business. But selecting the right ERP software can be difficult. In this blog post, we will understand the key steps to selecting the right ERP software. We will also try to understand if you should use ERP software in your manufacturing business.

Understanding The Need for ERP System

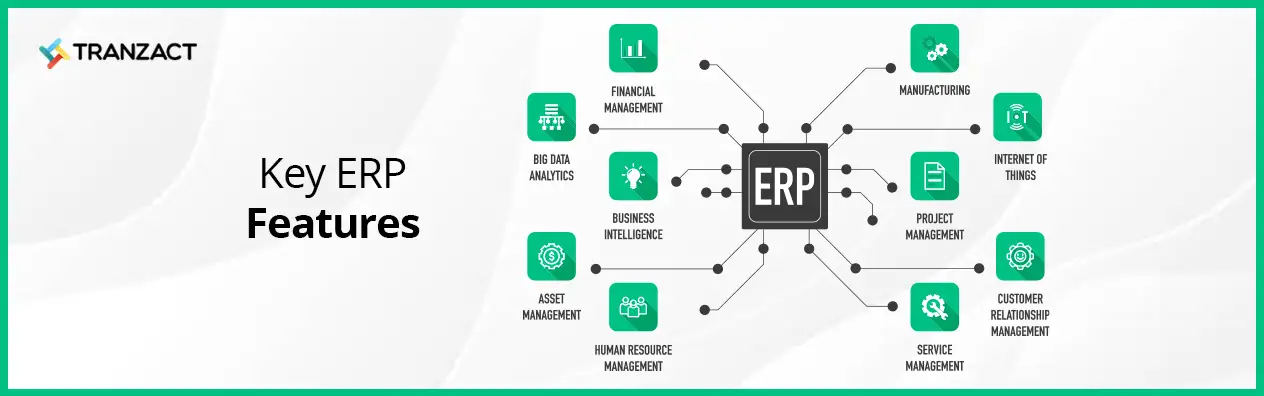

ERP systems have long been used by manufacturers for managing their operations. ERP software provides useful functionality and tools to manage sales, inventory, purchase, payment, and production processes.

An ERP for manufacturing helps in inventory tracking, warehouse automation, and connecting various departments in a place. It creates a web between different aspects of a manufacturing business and integrates them all. It also provides inventory insights and minimises manual tasks in overall operations.

Factors To Consider When Choosing ERP

Choosing the right ERP system for your business depends on various factors. Let’s go through some common factors that will help you choose the right manufacturing ERP software for your company.

1. Business-size

The first factor to consider in an ERP solution is the size of your manufacturing business. The best ERP system for manufacturers is the one that easily adapts to teams of all sizes. Its capability should match your production requirements and capacity.

2. Scalability

The second factor to consider is scalability. As your business grows, you will have to put more effort into inventory management, BOM management, and streamlining the supply chain. Therefore, you should choose one of the types of ERP systems that can grow with you.

3. Cost-Effectiveness

Traditional or legacy ERP systems often need expensive infrastructure to set up. They also require experts for set up and training. A cloud-based ERP system for manufacturers can be the best option. This is because it requires very few resources to implement and works on a remote server. This reduces the costs related to workforce and manual working.

4. Integration

When you are looking to select the right ERP system, you should check its compatibility with other software. This will help with smooth data flow, synced operations, and automation in different business functions. A good ERP should not only integrate with other tools like Tally, Excel and WhatsApp but also have shared data collection and business process integration.

5. Accessibility

Make sure to choose a system that is easily accessible from any device. You should also check the software's interface to make sure it is comfortable to use. The best ERP system for manufacturing should have all the required modules easily accessible for your operations.

6. Support

Legacy ERP system receives almost no support and very limited updates. But, the cloud ERP software is regularly updated and has continuous support. That's why, you should go with cloud ERP rather than traditional ERP.

Steps To Choose the Right ERP System For Manufacturers

Choosing the right ERP system for manufacturers is an important decision as it helps to optimize processes and run operations effectively. Here are the 10 steps to select the right ERP software that fits your manufacturing needs.

1. Identify Business Needs

Start with finding the bottlenecks in your business and choose the manufacturing ERP software that can solve them. This can improve inventory management, reduce production lead time, and even improve product quality.

2. Research Options

After understanding the goals, make a list of the ERP providers. Compare their industry experience and reputation. You can also read case studies or ask other manufacturers for suggestions on the ERP solution.

3. Cost And ROI

It is important to consider the cost of an ERP system for manufacturers that fits your budget with a valuable investment. You should also check the ROI (Return on Investment) by tracking key metrics such as improved productivity, reduced lead time, and cost savings.

4. Create RFP

Request For Proposal (RFP) is formal documentation that is sent to an ERP vendor. This letter may include your ERP requirements for your core business with the input of your team. RFP will give the provider detailed information on your needs. This makes it easy to implement your ERP system.

5. Request A Demo

Before implementing any ERP system for manufacturers, you should ask for demos from your selected vendors. Schedule a demo with your vendors and see if ERP for manufacturing is suitable for solving inventory management challenges and other problems in your manufacturing business

6. Implementation Plan

Discuss the implementation planning from your vendor. Set a timeline and an estimated budget for the implementation. Discuss the data that you want to transfer your old data to the new system. Make sure to have enough time for testing before the final implementation.

7. Access Support

ERP implementation can have different levels, which can disrupt your business operations. Here, you can ask for support from your vendor to provide complete planning. A cloud-based ERP system for manufacturers can be one option that requires fewer resources and is less time-consuming.

8. Configure Customization

The best ERP system for manufacturing will allow customization options as per your business needs. Another option is to choose the cloud-based inventory management system. They are not only customizable and flexible but can be integrated and accessed easily.

9. Install Software

When you want to install ERP software in your manufacturing business, a vendor takes care of everything. The data transfer is also included in this process if you are already using any other software. Select a vendor that will help with new and existing data during installation.

10. Training Staff

After installation, the vendor will train your staff about the ERP system for manufacturers and its functionality. A reliable ERP provider will provide manual and technical assistance for your training program. You can ask your vendor to customize a user-friendly dashboard and easy-to-access functionality.

Best ERP System for Manufacturing: Best Options For Your Business

The main focus of any manufacturer is to maintain the BOM (Bill of Materials), accounting system, and inventory, and streamline the supply chain. You can find many ERP system for manufacturers that can help you with that. Some of the best ERP options are mentioned below.

- Oracle NetSuite ERP

- SAP

- Tally Prime

- Vyapar

- Odoo

- Procuzy

Choose TranZact To Effectively Manage Your Manufacturing Business

The right ERP software will manage the whole manufacturing operation of your manufacturing SME. Today’s advanced ERP system for manufacturers provides complete functionality to improve overall productivity. However, SME manufacturers may not require a complete solution. Their needs are different, and an ERP might be too much for the job. Here, it becomes very important that you choose the right software.

TranZact is an alternative to ERP that helps you do demand forecasting, production planning, tracking, and much more. It is the easiest software made especially for Indian SME Manufacturers. The unique thing about TranZact is that it is flexible and affordable. It takes care of all your manufacturing processes from enquiry to dispatch. Automate your work order management, accounting process, BOM, and much more with TranZact.

FAQs

1. What is an ERP System for manufacturing?

ERP systems for manufacturing are software that contains functionality and tools to effectively track production processes, finance, inventory, and more things.

2. What are the main factors in choosing an ERP system for manufacturers?

The main factors in choosing the right ERP system for manufacturing businesses are:

- Size of a business

- Scalability

- Functionality

- Integration process

- Customization Options

- Affordability

- Easy Updates

3. What are the selection criteria for ERP systems?

The selection criteria for ERP system include:

- Determining business needs

- Researching ERP vendor

- Defining the budget

- Creating RFP

- Requesting demo

- Planning implementation process

- Analyzing the ongoing support

- Configuring the software

- Installing the ERP

- Considering the training process

4. What are the 5 key features of an ERP system?

The five key features of the ERP system are:

- Inventory Management

- Supply Chain Management

- Order Fulfillment

- Finance And Accounting

- Analytics And Reporting

5. Why is ERP selection important?

Selecting and implementing the right ERP software will help you improve your business productivity, solve difficulties in the accounting and finance process, track inventory in real-time, and manage other important things.

6. Why would a company choose to implement an ERP system?

Companies need to implement ERP software to improve their accounting process, enhance productivity, and organize the workflow.