Manufacturing ERP systems can be very beneficial for manufacturers handling inventory, production, purchase, and sales. But, finding the perfect ERP implementation system is a complex task and requires a lot of research. Every manufacturing business wants to find a system that can offer all the required features under budget.

If you are looking for a manufacturing ERP system for your business, this blog post will provide you with all the necessary information for ERP selection criteria. You will understand the features that an ERP solution should have and be able to choose the best manufacturing ERP solution.

What Is Manufacturing ERP System

ERP or Enterprise resource planning is a system that creates a centralized platform where all the operations and processes of a business are dealt with. ERP Systems in the Manufacturing Industry go beyond the regular ERP functions. These systems can improve the workflow by working on production planning, scheduling, bills, payments, quality control, and inventory management.

Imagine that every department of your business is using a different software and you have to go back and forth to understand the different departments. An ERP system works as a central computer connected to all department computers. The ERP system builds a client-server model where different teams can integrate and function together.

Importance Of Choosing The Right ERP System For Manufacturing

There are many reasons why choosing the right ERP system for manufacturing is important. Here is a list of reasons why you should leave manual management and switch to a Manufacturing ERP system for your business:

1. Improving Production: A Manufacturing ERP system can automate most tasks based on demand, capacity, and material availability. It can automate and improve scheduling, material management, and logistics. This improves overall production efficiency.

2. Increasing Productivity: It can give teams real-time insights into data and make better decisions. This helps you use your resources more effectively and estimate production, improving overall productivity.

3. Team Collaboration: A Manufacturing ERP system creates a centralized platform for collaboration and integration. Multiple teams across departments can work together and communicate in an ERP solution.

4. Better Inventory: The best ERP Manufacturing solution will let you auto-adjust stock from invoices and purchase orders to final goods. It can detect when the stocks are facing shortages and how to make stock levels better, find patterns, and reduce carrying costs.

5. Improved Quality: Quality for production is the priority for all businesses and customers. The software makes sure that the quality standards are in place. You can identify trends with an ERP system and find the areas of defect and improvement as well.

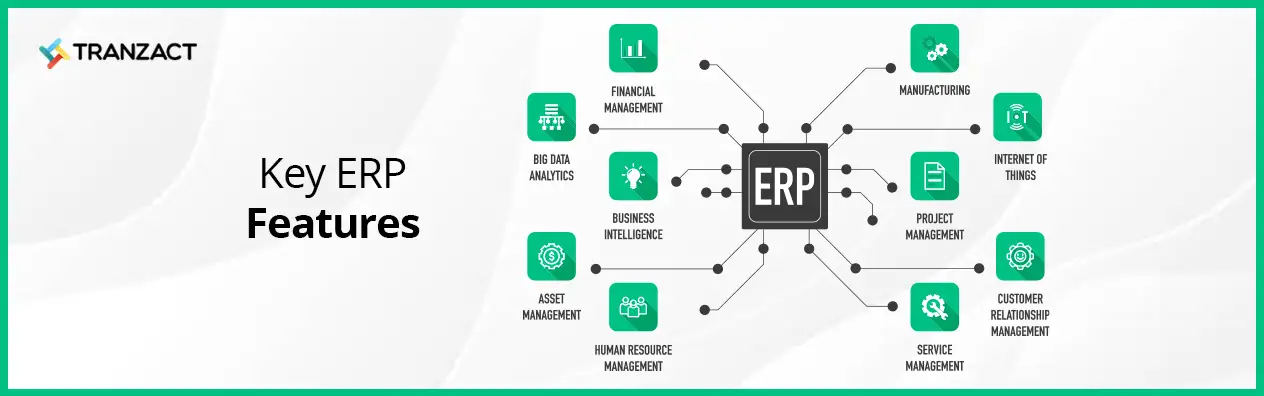

Key Features To Look For In Manufacturing ERP System

While getting an ERP for your manufacturing business, do in-depth research and make sure that your selection can satisfy all your business needs. Here is a list of 10 features you should look for while finding an ERP System for your Manufacturing Business:

1. Remote Access

Businesses should be able to access the software from any location and at all times. This allows the team to utilise and communicate anytime. This improves the convenience of handling the operational tasks of a business.

2. Customer Support

Good customer support will help you perform better. You can reach out to the system providers during issues and interruptions. A quick resolution can help to make sure there is no business loss.

3. User-Friendly

The system should have a user-friendly interface. Easy navigation is one of the most important features of manufacturing ERP systems. This will reduce the learning curve for your staff working on daily operations.

4. Security and Privacy

Every manufacturing business carries sensitive data. If this data gets leaked, you may face data breaches and cyber threats. Find an ERP software that takes care of security and maintains business privacy.

5. Real-time Reports

Real-time reports can provide up-to-date data. You need this data type for inventory, production, and financial performance. Accurate real-time data can help with prediction and better decisions.

6. Cost-Effectiveness

Find the total cost of using an ERP software. Consider initial investments, operational costs, and additional expenses before getting an ERP system. Make sure that the chosen Enterprise Resource Planning Software provides a good return on investment.

7. Industry Functions

Generic ERP Software may not be enough for you. For example, Indian SME manufacturers would not require all the features of an ERP. The best ERP software for the manufacturing industry will offer you specific functions related to your business.

8. Easy Customisation

An ERP solution for manufacturing should be able to adapt to future needs. Technology is changing every day, and new features are being introduced to the manufacturing market. Your ERP solution should record and improve with these changes.

9. Easy Integration

A Manufacturing ERP system should collaborate with existing software and systems of the business. These systems include CRMs, traditional accounting software, e-commerce platforms, etc. for example, Tally for accounting.

10. Future Scalability

Finally, make sure that your selected ERP solution for manufacturing can scale with your business. An enterprise grows over time and gets new and repeat customers. Hence, you shall select an ERP system that can adapt to the increased sales, volumes, and users.

Consideration for ERP Selection and Implementation

There are multiple selection criteria to pick a Manufacturing ERP System that fits your needs. Here is a list of a few things to keep in mind:

- Look for a customizable Manufacturing ERP System that can adapt itself to your needs.

- Your ERP software should have a user-friendly interface.

- Evaluate if your selected software can be integrated and implemented with the required software.

- Consider buying, implementing, training, and execution costs for it.

- Your ERP system shall scale with your growing business without failure.

How To Choose The Best ERP System For Your Small Manufacturing Business

After knowing the key features of erp, here are some steps you can perform when choosing a Manufacturing ERP System for your business:

1. Identify Business Needs: The first step is to identify the needs of your business. See if you have a weak production process, lack inventory management, or inefficiency in any other operations. Be clear in defining your goals and learn about the functionalities you need.

2. Creating A Budget: The next step is to decide on a budget. Look for the best ERP solution for the manufacturing industry. You need to consider the financial resources of your business and align them with the ERP cost.

3. Researching The Market: Your next step should include deep research for the required ERP software. Look for ERP solutions that you think can work well with your business structure. Consider customer reviews, recommendations, and the credibility of the brand.

4. Advice from Stakeholders: You should involve stakeholders and department experts in final decision-making. The departments may include production, inventory management, finance, and IT. The stakeholders will help you identify the features you want.

5. Comparison And Selection: Now that you have a list of compatible ERP systems, the next step is comparison. You can talk to multiple vendors and tell them about your business needs. Check features, functionality, ease of use, and scalability of all ERP systems.

Find Success With TranZact Manufacturing ERP Software

To find the Best ERP software for manufacturing industry, you shall look for the required features that your business needs. Furthermore, a manufacturing ERP system implementation can improve the workflow. You should consider creating a list of problems your business wishes to solve. Finally, find an ERP system that aligns with these needs and offers maximum features.

TranZact is the perfect software that Manufacturing businesses can use. TranZact is not an ERP but a software made especially for Indian SME Manufacturers. This platform provides many features and has been trusted by more than 10,000 SMEs. TranZact offers 24*7 customer service and gives access to data at any time and any place.

FAQs

1. What are the main factors in choosing an ERP system for manufacturers?

There are numerous factors to consider when choosing an ERP system for manufacturers.

- Scalability

- Industry-Specific functions

- Integration ability.

- User-friendly interface

- Budget-friendliness

2. What is ERP for manufacturing?

An ERP system for manufacturing is a software-based solution for centralization of operational tasks. Businesses can integrate with multiple departments and manage core manufacturing tasks.

3. What is an ERP system in manufacturing?

Here's what a manufacturing system in Manufacturing can do!

- Production and Planning

- Scheduling tasks

- Managing payment and bills

- Quality Control and management

- Inventory management

4. What should I look for in an ERP package?

Here is a list of features you should look for in an ERP package.

- Industry-defined features

- Scalability and Growth features

- Integration with production, warehouse, etc

- User-friendly software

- Total subscription and ownership costs.

5. What is the function of ERP in the manufacturing industry?

An ERP system plays a significant role in the manufacturing industry.

- Improving efficiency

- Smooth production

- Improved collaboration

- Quality and consistency

- Customer satisfaction

6. Which is the best manufacturing ERP software in the industry?

The best ERP software for the manufacturing industry is TranZact! It lets businesses track stock shortages. More than 10,000 MSMEs trust TranZact to handle their business. You can access inventory, sales, and purchases for free.

7. What would be an example of manufacturing ERP software?

There are multiple ERP software for manufacturing available in the market. However, the best manufacturing ERP system is TranZact. You get the best features, including inventory management, sales and purchase, production management, etc.

8. How is ERP useful in manufacturing industries?

An ERP solution is perfect for manufacturing industries. They can help save time and increase efficiency. Businesses can get real-time insights and improve their workflow. Further, they can get help when making business decisions.