What Is Inventory Optimization?

Efficient inventory optimization can protect you against demand and supply variations and help to reduce overall costs. A significant reason for the success of many manufacturing businesses is that they optimize inventory well. And that's why, inventory optimization software is a critical component of the functioning of supply chains.

This blog will help you understand the importance of inventory optimization, inventory optimization tools, and the detailed process for smooth supply chain inventory optimization management.

What Is Inventory Optimization?

Inventory optimization is the process of minimizing the inventory holding period and quantity of inventory held. It includes various functions to ensure that the business maintains accurate inventory levels while ensuring that it is able to meet customer demand effectively.

Inventory optimization for supply chain management involves forecasting demand for products, adjusting stock levels, and implementing strategies such as just-in-time production to ensure that inventory is neither overstocked nor understocked.

Supply chain inventory optimization is especially beneficial to businesses that want to maintain a saleable inventory that is always moving while using less capital in this process. By optimizing inventory, these businesses can reduce excess stock, minimize stock-outs, and improve overall profitability.

Read Also - Which Software Is Recommended For Inventory Management?

Why Is Inventory Optimization Important?

Inventory optimization and management are crucial as they ensure that the business incurs the least amount of costs to carry products. This section explains in detail the importance of inventory optimization services; read on to know more:

Reduce working capital

Optimizing inventory helps reduce unnecessary buffer inventory that cuts down working capital. It ensures that customers get the required product at the right time without holding too much inventory.

Smart inventory optimization tools such as inventory optimization software are known to reduce inventory holdings measurably so that the capital can be invested in other key business areas.

Inventory planning

Inventory optimization systems help facilitate inventory plans without stockpiling excess products. Businesses can set replenishment quantities and adequate safety stocks for individual teams. It also enables them to optimize allocations by proximity.

Eliminate supply-chain variations

With a centralized inventory system, you can get better visibility of production costs, procurement, and service necessities. You will notice reduced production and transportation expeditions and a seamless flow of other products.

Satisfy more customers

With the help of managed inventory through inventory optimization software, you can improve delivery, reduce your stockouts and satisfy more customers, thanks to demand alignment. This will drive brand loyalty and even increase the rate of return customers.

Transparency in the workplace

An optimized inventory helps your employees to become confident as they are well-informed of all inventory movements and controls. Such transparency enabled by supply chain inventory optimization management, facilitates lower costs, and shorter lead times, and downplays unnecessary handling and storage.

Employees can now ensure that the right products are being sold at accurate margins across the business. Read Also - Best Barcode Inventory Software in 2023

Inventory Optimization Process

The following processes help in building a successful inventory optimization function:

Demand forecasting

Identifying demand is one of the most important steps of inventory optimization for supply chain management. This is done through sales forecasts and assessing inventory history. Informed decisions made through planning also help to estimate expected revenue for the period.

This is also important when businesses plan flash sales, and festive offers and undertake operational tasks of hiring more staff or renting more space for business growth.

Managing product life cycles

Every new product in the market creates future demand depending on the impact generated and the popularity gained. Hence, every seller must be able to identify the correct stages of the product life cycle for each stock-keeping unit (SKU). Understanding if the demand for the product will grow exponentially or be stable after a specific time can help to decide which products should be kept in stock and which ones to drop.

Standardizing inventory policies

Supply chain inventory optimization supported by a proper inventory policy can help employees identify and accurately label critical stock-keeping units. This ensures a steady cash flow and even helps to keep tabs on indispensable inventory items.

Accounting for uncertainties in demand and supply

Manufacturing businesses need to efficiently stock and restock products to avoid the risk of customer churn. Having a reliable network of vendors helps to maintain backup methods to ensure on-time procurement of stock-keeping units. It enables the supplier to manage regular schedules and delivery patterns.

Tracking changes in buyer behavior

An inventory management system provides detailed reports about stocks in the warehouse. This data and analytics help business owners to understand customer behavior, and facilitate better prediction of phased-out items and the best-selling items in the future.

Modern inventory management software comes to the rescue to generate insightful data points relevant to buyer behavior. Read Also - Best Cloud-Based ERP Software in 2023

Automating inventory management and going digital

Manual inventory management is often faulty and can lead to poor service, delays, frozen capital, and large amounts of unsold items. Product manufacturers can benefit from the automation of inventory management as it can eradicate manual errors, send overstocking and understocking notifications, and slash maintenance costs.

Factoring promotional campaigns

Putting unsold products in storage increases maintenance costs while withholding effective capital usage. This can complicate forecasting and hinder inventory optimization. To unload excess inventory and optimize the inventory, activities such as end-of-season promotional campaigns are helpful.

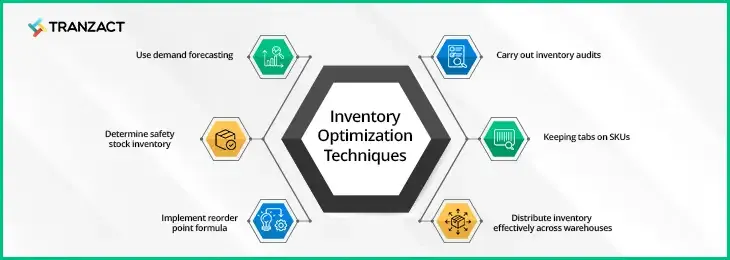

Inventory Optimization Techniques

The main purpose of inventory optimization is to maintain a balance between what you purchase, how much you purchase, and when you purchase it. Optimizing inventory with the right inventory optimization formula enhances business investments and helps to achieve business objectives.

The following are the best inventory optimization methods and techniques to help your business accomplish this -

Use demand forecasting

You can make informed supply decisions to estimate total revenue and sales for any upcoming period with the help of the right inventory optimization tools. Forecasting demand is easier with the help of historical order data that can provide insight into sales trends. Accurate demand predictions help you to make better decisions to save money, improve supply chain management and deliver an upgraded customer experience.

All manufacturing teams are accurately informed about the purchase required for stock-keeping units. This allows them to fulfill orders on time and reduces the chances of excess inventory becoming obsolete in the long term.

Determine safety stock inventory

Buffer inventory or safety stock refers to the excess product kept on hand in case of emergencies or supply chain failures. It requires inventory teams to account for safety stock and park resources for the same on a regular basis.

To know the ideal amount of safety stock, you will need all of the following for each SKU:

- Maximum lead time

- Maximum daily usage

- Average lead time

- Average daily usage

Implement reorder point formula

It is essential to know the amount of minimum stock inventory and the optimal times to reorder. The formula for calculating a reorder point is-

ROP = (Average daily demand * Lead time in days) + Safety stock

Lead time accounts for the time it takes to process the order, ship the order, and also any other delays that may occur.

Carry out inventory audits

Inventory optimization services facilitate regular audits that cover all daily and ad hoc warehouse transactions. It also monitors holding costs like inventory shrinkage, storage, staffing, and depreciation closely.

These figures can be used to calculate and eliminate any major discrepancies. Digitized inventory monitoring helps to conduct inventory audits seamlessly.

Keeping tabs on SKUs

Syncing stock-keeping units (SKUs) within inventory management systems helps you update, track and manage products across the distribution network. It can help to avoid overselling or running out of stock early.

Inventory optimization helps to view real-time inventory levels, and merge the same products across all points of sales to keep tabs on the SKUs.

Read Also - ERP Implementation: Comprehensive Guide to Success

Distribute inventory effectively across warehouses

It is key to ensure that your inventory fulfillment flows are monitored across multiple warehouses. This can be done by using different distribution channels, and by optimizing supply chain opportunities for lower-cost order delivery.

Strategic distribution of SKUs using inventory optimization services across multiple fulfillment centers helps to reduce shipping costs enabling efficient order delivery. With modern fulfillment networks, you can gain insights into SKU performance at each location and make better inventory decisions.

This ultimately ensures you have the right product in stock, ready to ship when needed. It also helps in reducing inventory fluctuation and improves cash flow by lowering obsolescence costs.

Read Also - What Is Cycle Inventory?: Definition, Importance and Formula

Challenges in Inventory Optimization

While implementing inventory optimization enhances business capabilities, it can be complex and challenging for businesses. Some of them are listed as follows:

Offset supply chain disruption

Supply chain disruption is challenging for manufacturers due to natural disasters and global lockdowns. Your inventory optimization process should contribute to a robust and unbreakable supply chain that can prevent stock outrages and fulfill customer demands on time.

Volatile customer demand

Keeping up with ever-changing customer preferences can pose a challenge. In case of a sudden demand increase for a particular product, only those who have it in stock already can pull off the profit.

The ones without supply either miss out on sales opportunities or end up paying higher acquisition costs to manufacture the same. Moreover, after the demand subsides, businesses may be left with dead stock. Therefore, they must optimize inventory accurately through forecasting and other related tools.

Order fulfillment momentum

Businesses without automated inventory optimization are prone to human errors and unhappy customers. Moreover, supply chain disruptions and operational mismanagement can be upsetting for inventory optimization.

It may lead to inventory personnel being overwhelmed by the challenges of replenishing stock, maintaining sales, and moving stalled inventory while satisfying customers. Optimizing inventory levels with inventory optimization software helps to avoid these challenges and offers manufacturing businesses a competitive edge.

Read Also - Best Production Planning software

How Can TranZact Help You in Inventory Optimization?

Optimization and inventory management help to outline demand and supply. It is ideal for balancing investment restrictions against business goals and fulfilling targets across all SKUs. TranZact is an end-to-end business automation software with a detailed focus on sales, purchases, inventory, and production functions. TranZact's inventory management system offers a systematic inventory dashboard that provides both a quick overview and a detailed view of stock valuation, all in one place.

It is specifically built for Indian manufacturing SMEs and supports them with inventory optimization by centralizing inventory management and stock reporting. It provides a quick analysis of top-selling items and top-bought items, thereby assisting with error-free stock management.

With its integrated cloud-based management system, this platform ensures fully automated documentation which can track inventories in real-time. It equips businesses to avoid scenarios of overstocking and under-stocking and helps to save costs.

With the help of inventory management software like TranZact, you can access an intelligent dashboard to simplify inventory analysis and make informed decisions quickly. This makes it the best tool for inventory control and optimization for small and medium-scale businesses!

Why Should You Optimize Your Inventory?

An ideal inventory optimization system saves you considerable capital by right-sizing your inventory, freeing up capital for investment in other business operations, and reducing excess in-hand stock. When you modernize your inventory optimization strategy, you can quickly notice valuable business growth. Achieve measurable improvements with the help of TranZact's inventory optimization software. It comes with a free forever plan, with all base features free for an unlimited period.

FAQs on Inventory Optimization

1. What is meant by inventory optimization?

Inventory optimization refers to the process of maximizing inventory efficiency by minimizing stock levels while ensuring adequate availability to meet customer demands.

2. How is inventory optimization done?

Inventory optimization is achieved through various techniques such as demand forecasting, implementing just-in-time inventory practices, and utilizing advanced inventory management software. Other important steps for inventory optimization include conducting regular inventory audits and establishing effective inventory replenishment strategies based on demand patterns and lead times.

3. What are the 4 types of inventory control?

The four types of inventory control are ABC analysis, just-in-time (JIT) inventory control, economic order quantity (EOQ), and materials requirement planning (MRP) techniques.

4. What is inventory strategy in supply chain management?

Inventory strategy in supply chain management refers to the plan and approach taken to manage and optimize the levels. It looks into the placement, and movement of inventory throughout the supply chain to meet customer demands while minimizing costs.

5. What is the optimal level of inventory?

Optimal inventory levels are the ideal inventory quantities your company should have on hand. Your stock levels should match your actual customer demand, so there is always enough inventory to fulfill demand.

6. What are the benefits of inventory optimization?

The benefits of implementing inventory optimization are -

- Efficient stock and production operations

- Reduction in production and transportation expeditions

- Improved customer service

- No disruption of flow for other productsGet products to market faster