Digital transformation is rapidly changing production and supply chain management in the manufacturing industry. The world is now shifting to the fourth industrial revolution, which is defined as Industry 4.0. This digital transformation in manufacturing includes the usage of smart methods like cloud-based ERP software, IoT (Internet of Things), automated manufacturing systems, and many more.

In this blog post, we will understand how digital manufacturing transformation is beneficial to Indian SMEs. We will also learn about the challenges and latest technologies, with some examples for achieving financial success in your manufacturing business.

What Is Digital Transformation In Manufacturing?

Digital transformation in manufacturing is the way to handle manufacturing operations by adopting advanced technology. It includes the implementation of digital technologies to improve every aspect of the manufacturing cycle time.

From product design and procurement of raw materials to production and supply chain management, this digitization helps optimize operations, improve efficiency, and improve CRM (Customer Relationship Management).

Why Should Manufacturers Implement Digital Transformation?

Digital transformation for manufacturing companies is needed to remain competitive, improve product quality, secure safety, and generate revenue with sustainability. Digital transformation for Indian manufacturers improves the quality of output, reduces the rework, and increases customer satisfaction.

Upgrading to digital solutions improves the safety measures that avoid injuries and accidents. Implementing new technology can improve productivity and increase your company’s value in the marketplace.

Benefits Of Digital Transformation In Manufacturing Industry

Digital transformation has provided numerous benefits that improved productivity and overall business performance. Let’s have a look at the following advantages.

1. Increase Productivity

Digitalization in manufacturing allows the automation of repetitive tasks, which helps reduce production lead time. Implementing cloud-based software can allow you to access the location of your inventory, lower the cost of production, and increase the quality output.

2. Improve Quality

Digital technologies allow Indian SMEs to monitor and control the ongoing manufacturing process. It helps you detect defects and make quick decisions to solve the problem. This proactive approach contributes to producing high-quality products that increase customer satisfaction.

3. Reduce Manufacturing Cost

Implementing the digital solution in the Indian manufacturing business can minimize the downtime in production. It also allows you to monitor the equipment's performance and schedule the maintenance before it gets bigger. It reduces the maintenance cost, optimizes energy consumption, accurately forecasts the demand, and ultimately reduces the manufacturing cost.

4. Supply Chain Optimization

The use of inventory management software is one among other benefits of digital transformation in manufacturing. It provides real-time visibility on inventory tracking and allows on-time procurement of raw materials. It helps you with better the supply chain, smooth operations and timely deliveries.

5. Reduces Accidental Risks

Safety is one of the most important factors to consider in manufacturing business. Digital transformation for manufacturers in India helps implement advanced technologies for training and safety programs. You can create safety guidance for the workers and provide support to safely complete tasks to minimize accidents on site.

6. Better Decision-Making

Implementing technologies like IoT devices and analytical tools helps to generate vast amounts of valuable data. Indian manufacturers can use this insight to make actionable decisions in production management. You can make strategic manufacturing plans for the future and have a continuous process of improvement.

7. Improve CRM

The digital transformation in manufacturing businesses is beneficial for end customers, too, as they can get improved product quality and faster delivery. Minimizing manufacturing costs can also allow customers to buy inexpensive products. This will help to improve customer relationships and build loyalty among your targeted users.

Challenges Of Digital Transformation In Manufacturing

With the digitalization in manufacturing, an ever-evolving industry, you may face several challenges that can impact your business growth. Here is a quick list of common challenges with solutions.

1. Right Technology

The success and sustainable growth of manufacturing depend on having the right tools for the job. For example, you can use cloud manufacturing software which is scalable for financial success. Your new technology must adapt your business goals and provide measurable values to make better decisions.

2. Managing Changes

Managing the changes that come with digital transformation becomes difficult for Indian SMEs who are still dependent on traditional methods of manufacturing operations. Businesses that are willing to adopt new technologies can benefit by collaborating with the right service partners/vendors. They can help you make a customized manufacturing digital transformation roadmap for easy implementation.

3. Training Employees

Skillset is another challenge that comes with the shift of digital technologies, and it requires a knowledgeable workforce to utilize the new tools. In digital transformation, you need to provide enough training to employees on how the new system works. Cloud-based software can be a great choice for your manufacturing business in India as it requires less training to improve workflow.

4. Integrating Technology

SMEs in India face problems integrating the manufacturing software with the existing ERP system. The legacy ERP system replacement, which often has limited scalability due to a lack of trendy modules and technologies, can solve the problem. You can consult a reputable company that offers the best manufacturing managed services to help run the existing systems with modern cloud-based softwares.

5. Managing Data

Businesses using the legacy system often face problems with data management during digital transformation in manufacturing process. They are unable to trace and access the ability of product information as they are shared with various departments. Switching to cloud-based ERP software can allow you to transfer such information while collaborating with various sectors and make digital transformation effortless.

6. Cyber Security

Increased connectivity can expose manufacturing systems to potential threats. As a cloud-based system, it becomes easy for hackers to navigate the manufacturing software and access valuable data. It is recommended to choose a reputable vendor that offers effective cybersecurity measures such as encryption, firewalls, and regular system updates to safeguard against cyber-attacks.

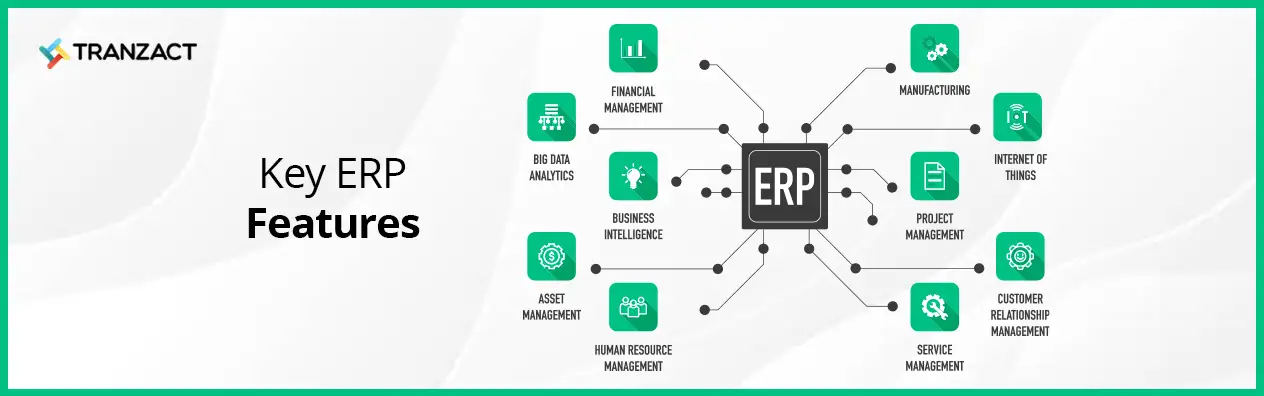

Key Technologies Driving Digital Transformation In Manufacturing Industry

Manufacturing businesses need to handle huge amounts of data, and for that, they need to use analytics for digital transformation. It requires a setup for interconnecting the departments, stakeholders, and suppliers for effective communication. The digital transformation tool provides information about manufacturing operations and allows you to make the right predictions and make actionable decisions.

Here are some of the technologies that are being used for the digital transformation in manufacturing and replacing the traditional way of operations.

- IoT (Internet of Things)

- Robotics And Automation

- Big Data Analytics

- Cloud-Based Manufacturing Softwares

- AI (Artificial Intelligence)

- ML (Machine Learning)

- 3D Printing Technology

- AR (Augmented Reality)

- VR (Virtual Reality)

Key Components Of A Successful Digital Transformation In Manufacturing

Modern manufacturing businesses are more focused on improving their operations, manufacturing high-quality products, and increasing CRM (Customer Relationship Management). Indian SMEs better understand that improving the workflow of their organization can increase efficiency.

They often go with a strategic approach to train their employees to use digital transformation tool for manufacturing with the effective plan discussed below. A clear vision for digital transformation is important. This provides purpose and direction for decision-making and resource planning. Appointing leaders at all levels of the organization encourages collaboration and increases the importance of digitalization in manufacturing.

Selecting the right software provider to provide a manufacturing digital transformation roadmap makes sure the integration of advanced technologies that are compatible, scalable, and secure. Implementing data analytics tools and processes to collect and analyze data yields actionable insights across various operations.

Investing in training programs and workforce development helps employees use new technologies effectively. Regular evaluation of the digital transformation process, identifying issues, and solving them for continuous improvement is important for success.

Examples Of Digital Transformation In Manufacturing Industry

"Modern manufacturing" is one of the best digital transformation examples in manufacturing industry. The term is often used to describe the use of digitally advanced technologies and automation tools that effectively communicate with other systems and gather valuable insights about operations.

Smart manufacturing can be applied to all aspects, including production management, quality control, and supply chain management. These technologies may include highly customized CNC (Computer Numerical Control) machinery like barcode technology and an RFID (Radio Frequency Identification) system for inventory tracking.

These tools make processes more productive by improving quality control, production scheduling, and better inventory planning.

Future Proof Manufacturing Operation With TranZact - A Digital Transformation Tool

SME manufacturing companies in India often struggle with inefficient production cycles, which results in high wastages and last-minute delays. Digital transformation in manufacturing with TranZact helps you easily track the production process, estimate the cost, and share multi-level BOM (Bill Of Materials) with the suppliers.

It helps you maintain the procurement life cycle throughout the manufacturing process to promote efficiency in the organization. TranZact also offers automated inventory management, MRP (Material Resource Planning), and sales and purchase management.

Choose TranZact now to effectively execute all your manufacturing operations with ease and drive financial success in your business.

FAQs

1. What is digital transformation in manufacturing?

Digital transformation in manufacturing is the process of adapting new technologies to improve the production process while considering changes.

2. What Are the Key Technological Drivers Behind Digital Transformation in Manufacturing?

The key technological drivers behind digital transformation in manufacturing are:

- Cloud-Based ERP Software

- Industrial IoT Sensors

- RFID and Barcode Scanner

- Big Data Analytics

- AI and ML

- Robotics and Automation

- Additive Manufacturing

3. How can SMEs develop a digital transformation roadmap for manufacturing?

SMEs can develop a digital transformation roadmap for manufacturing using the following steps.

- Clear Vision and Objectives

- Stakeholder’s Engagement

- Strategic Planning

- Technology Integration

- Training Program Implementation

- Evaluation and monitor

4. What are the emerging trends in digital transformation for manufacturing SMEs in India?

The emerging trend in digital transformation for manufacturing SMEs in India is the introduction of modern manufacturing. This includes cloud-based tools and the use of VR and AR technology for better visibility.

5. What are some examples of digital transformation initiatives in the manufacturing industry?

Some of the examples of digital transformation initiatives in the manufacturing industry include:

- Automation of production process.

- Use of artificial intelligence.

- Replacement of humans with robots.

- Introduction of cloud-based manufacturing software.

6. What are the essential digital transformation tools for manufacturing companies?

The essential digital transformation tools for manufacturing companies are:

- Project Management Tools

- Communication Tools

- CMS Platforms

- Cloud ERP Solution

7. How do managed services support digital transformation in manufacturing?

Managed services support digital transformation in manufacturing by giving access to information, talent, and tools to have a digital workspace.

8. What financial benefits can SMEs expect from digital transformation in manufacturing industry?

The financial benefit SMEs can expect from digital transformation in the manufacturing industry is reduced operational costs through improved capital and labor utilization.