The chemical industry is an important part of modern manufacturing. But, small and medium-scale businesses face multiple challenges in this sector. These businesses have to work with strict compliance. With this, they need accurate inventory control and data management which can be a complex task for many. ERP software for chemical industry and related systems can solve required chemical industry business management issues.

In this blog post, we will talk about the meaning of Cloud-based ERP software, features of chemical industry ERP, faced challenges, and solutions.

What Is ERP For Chemical Industry?

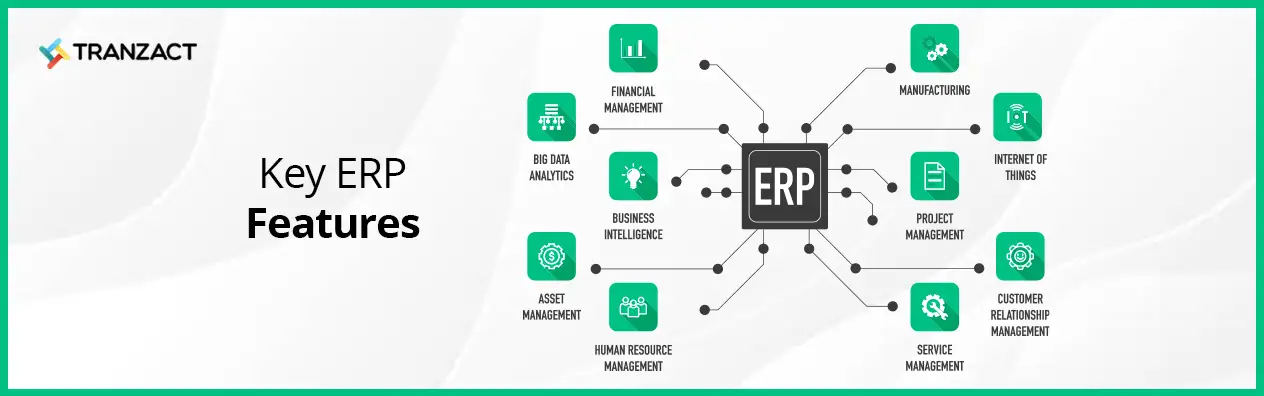

Enterprise Resource Planning software helps to look after business operations, including inventory management, planning, production, sales, and other services from a single dashboard. An ERP software for chemical industry takes the management process one step further. You can make sure regulatory compliances are met with a chemical ERP solution.

If you pick the right technology for the chemical industry, you can focus on batch tracking, communicate with clients, and make sure of efficiency in business operations. The cloud-technology is for storing large data amounts and records without hassle. You can get help with scalability and use the ERP system from anywhere at any time with a cloud-based ERP solution.

Why The Need of ERP Software For Chemical Industry?

Every manufacturing industry needs an efficient management system for improved workflow. Here's why chemical manufacturing ERP software is important.

- To connect multiple departments, including sales, production, inventory, and purchase with a chemical industry ERP system. This removes workflow complexity and allows every team to come on the same page.

- To get real-time insights from every department. Tracking helps in analyzing where your business processes can be improved, and costs can be reduced for profitability.

- To work on regulatory compliances and help you with regular audits through report generation.

- To keep track of the incoming and outgoing cash with the purchase module of the best ERP for chemicalmanufacturing software. This helps in finding if your customers are paying on time and your business is generating profits.

Challenges Faced By Chemical Industry Manufacturers

The chemical industry, like other manufacturing industries, faces unique challenges. Let's look at some challenges faced by chemical industry manufacturers.

1. Compliance & Regulations

Safety is the priority in any chemical industry. The government has strict laws to make sure of smooth workflow and safety in chemical industries. Challenges faced by manufacturers include tracking raw materials, maintaining data records about production products, and following compliance regulations and industry standards.

2. Inventory Management

The chemical industry deals with multiple raw material types and products. You need to maintain a record of every raw material from procurement to the sale. Some manufacturers fail to control and keep a record of their storage space, and stocks, and face challenges with stock management. While understocking will lead to disturbance in production schedules and unhappy customers, overstocking brings losses because of unused resources.

3. Production Problems

Proper schedules need to be created for resource allocation and manufacturing. These sequences help in achieving operational efficiency. Chemical manufacturing businesses need to identify the shortcomings in their production and sequencing process.

4. Real-time Data

The chemical industry requires constant monitoring and real-time data from every department. If the data is not up-to-date, you may face issues with the decision-making process and errors later. A centralized platform that connects all systems and provides real-time data can help with this challenge.

Features Of ERP Software For Chemical Manufacturing Industry

An ERP system should offer the required features and functionalities that can help a business scale and work efficiently. Here are some features that are must-haves for every chemical industry ERP software.

1. Inventory Control

Chemical ERP software can help you control inventory levels with ease. You track sales, communicate with suppliers and buyers, and maintain only the required stocks. This makes sure of timely manufacturing and testing of products, making sure of quality control, and timely product delivery to the customers.

2. Compliance Management

Chemical industries work with risky products. ERP software helps maintain data so that every raw material after procurement is on record. Further, the ERP system tracks and creates real-time reports of manufacturing and testing.

3. Transparency in Business

An ERP system allows real-time data monitoring and transparency among departments. You can manage sales orders, get help with product data maintenance, get insights about the manufacturing process, and know about your sales performance with a reliable chemical ERP tool.

4. Raw Material Procurement

Chemical Manufacturing ERPs can smoothen the raw material procurement process. You can handle purchase orders, track vendors and clients, maintain stocks, and help track the return on your investment. You can use an ERP system to send quotations to suppliers and vendors as well for communication and negotiation.

Benefits Of ERP For Chemical Industry

Every chemical industry works on accuracy, efficiency, and regulation adherence. ERP software for specialty chemical manufacturers should offer specific features. Here are some benefits offered by ERP software for chemical industry.

1. Streamlined Operations

An ERP system builds a central system that manages all business operations and connects different departments. An ERP software for chemical industry provides help with sales, production, inventory, and purchase. You reduce manual work and get access to a smoother workflow. You can process orders faster, sequence and schedule production, and record payments.

2. Real-time Visibility

A chemical manufacturing ERP software lets you keep an eye on real-time insights for every department. You can track inventory levels, and find where your production process stands. You can look over the invoices and e-bills to understand your financial performance. Real-time visibility helps you make data-driven decisions. Such decisions are more accurate and help in finding issues with your business when needed.

3. Meeting Regulations

The chemical industry needs to meet regulatory compliance. A chemical ERP system can help you track and manage raw materials. You can maintain batch records and generate required reports to meet the regulatory conditions. An ERP software for chemical industry helps you reduce the risk of not following mandatory industry rules and streamlines the process of regular audits and inspections.

4. Customer Satisfaction

Customers are the reason why businesses succeed or fail. ERP software helps you maintain data about the customers and their orders. You can fulfill their orders in a better and more accurate manner with ERP software for chemical industry. With this, you can create better relationships with your clients and communicate with them when needed.

5. Reduced Costs

An ERP software chemical manufacturing can help you cut down your business costs. You can improve resource allocation with inventory management and minimize waste, leading to cost reduction. ERP software helps you improve production management and remove manual work.

What Makes TranZact Different From Other ERP Software Systems

A traditional ERP system offers many features to a chemical industry manufacturer, but this software can be complex and expensive. Businesses have to train their employees and learn how to use these ERP systems efficiently.

TranZact provides exactly what a chemical manufacturer wants. You can get modules for sales, production, inventory management, purchasing, and e-bills. TranZact is user-friendly, easy to implement, and affordable for every SME owner. Special features, including batch monitoring and transparency for better decision-making are a part of this software. You can get barcode features for better inventory management as well. Let's TranZact now and get better workflow and efficiency.

FAQs

1. What is ERP for chemical manufacturing?

ERP stands for Enterprise Resource Planning. An ERP system for chemical manufacturing works in multiple parts of a business's operations with a single platform. This ERP software provides services for the following fields:

- Sales and Distribution

- Production and Planning

- Sequencing and Scheduling

- Inventory Management

- Purchase and Payments

2. What is ERP for chemical industry?

An ERP for chemical industry understands the unique needs of chemical manufacturers and provides custom services. You can track and manage production batches and control product quality with compliance. Inventory tools can help you manage your chemical product stocks and make sure that you are never over or understocked.

3. Are cloud-based ERP solutions suitable for the chemical industry?

Using a cloud-based ERP solution you can scale or downsize your sales and customers according to the market requirements. You save by reducing your hardware and software costs. Using cloud-based chemical ERP solutions you can track your business from anywhere at any time.

4. Is ERP suitable for both small and large chemical companies?

ERP solutions are suitable for small and large businesses in the chemical industry. Traditional ERP solutions may be expensive for small businesses. However, cloud-based tools can help provide you with cost-effectiveness and required services.

5. What should you keep in mind when selecting a chemical manufacturing ERP?

When selecting ERP software for chemical manufacturing, consider if it is designed for the industry, includes batch tracking and barcode features, offers transparency, has necessary integration capabilities, is scalable, comes from a reliable vendor, and has a manageable total cost of ownership.

6. What are the signs your chemical business needs ERP software?

Here are signs you need ERP software for your chemical manufacturing business: difficulty in maintaining records, managing stock levels, planning production, meeting compliance, and accessing real-time data.

7. What are the benefits of ERP software for process manufacturers and chemical companies?

Some benefits of using ERP software for process manufacturers and chemical businesses are smooth workflow, better resource allocation, improved visibility of operations, compliance with regulations, improved communication, improved order fulfillment, record maintenance, and reduced operational costs.

8. Which software is used in the chemical industry?

Multiple ERP software options are available for chemical manufacturing businesses, but they can be expensive for small businesses, and not all features may be used. TranZact offers a cost-effective solution with services ranging from inventory and production management to planning and purchasing, helping streamline operations and maximize benefits.