India has seen a dream of Digital India. From the latest science to the latest technology, everything should be available at the tip of one's finger. These were Prime Minister Narendra Modi's words during the launch of the Digital India campaign in 2015. 5 years after the release we can say that we have come a far way in achieving the dream of Digital India. SMEs the engine of the Indian Economy are also climbing the stairs of digitization slowly.

- Introduction

- Why Achieve Digitization Now?

- Helps to reach a bigger market

- To achieve a cashless economy

- Helps generate revenue.

- Security Of Company Data

- Value That Digitization Brings To Any Business

- Helps transcend geographical boundaries

- It Eases Marketing

- Helps Increase Sales

- Helps in the creation of brand

- Social Engagement that involves information sharing

- Way Forward

Introduction

Digitization is defined as the process of converting information into a digital format that is readable by computers. This format consists of numbers that are zeroes and ones. It is the use of digital technologies to convert information into a digital format. But when put to application in the real world, Digitization has the power to transform mankind into a realm that no one could have imagined a century earlier.

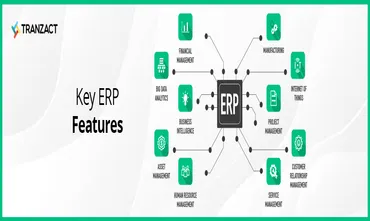

These technologies are remarkable and are converging together to transform the way businesses are conducted. Clever software, novel materials, better robots with IoT, new processes (notably 3Dprinting), data analytics, and a whole range of intelligent web-based services courtesy of AI and machine learning. The factory of the past was based on creating identical products. But now is the age of extensive customization which is what factories of the future would focus upon. For this to happen, our businesses would need to undergo a digital transformation.

WHY ACHIEVE DIGITALIZATION NOW?

Why does digital transformation need to be acted upon now?

SMEs can look within themselves as to what essentially their business needs to achieve. This could chiefly be -- ways to deliver value to customers, creating a competitive field for their products, generating revenue to sustain and expand their business, and data security.

Now does digitalization help them achieve this? It does.

How? Let's see.

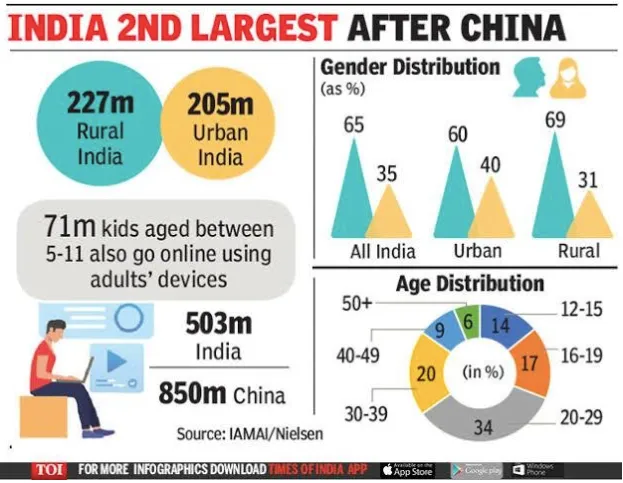

The digital penetration in our country has increased a lot due to the Government of India initiatives like Digital India and Skill India and the JAM trinity. We have a digital population of over 480 million. 390 million of that access the internet via their mobile phones. So by creating mobile apps and websites, one can provide better, quicker, and value-driven services to their customers.

For example, India has more than 200 e-pharmacies with more on the way, most popular among them being 1mg, Medline, Netmeds, Pharmeasy, and Myra. Not only this, few SMEs in the textile industry like Anouk and Gerua sold their products on established e-commerce websites and developed a loyal customer base. Later, they started their own websites as well.

Helps to move towards Cashless Economy

The benefits of a cashless economy are not a news to anyone. It saves the printing costs of currency and eliminates frauds of fake currency. Cash is difficult to trace. Illegal activities like tax evasion, black money, etc can also be carried out with cash. Therfore, going digital with all the all the transactions promotes a cashless economy. The government has initiated several schemes and programmes to promote digital payments in small businesses.

Read more on how becoming a cashless economy is important to India and what measures has government taken to promote it.

Digital technologies help to reach a bigger market

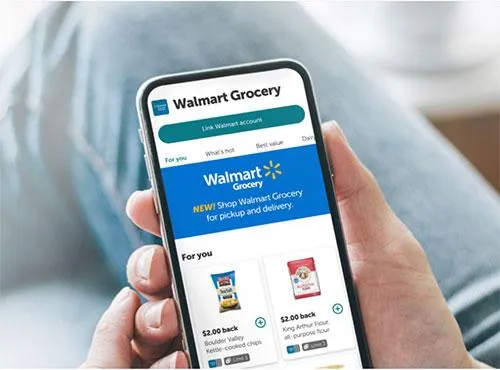

With the onset of pandemic going digital is the only way to survive for businesses. By achieving a transformation of the domain in their businesses, digital technology has altered competitive landscapes. Flipkart started this when they developed a strong digital infrastructure. It started a website from where the most basic household goods to the newest gadgets can all be accessed. It was essentially like having a virtual stroll down Walmart for Digital India

Many SMEs in Digital India followed the same model. Not only this, they took it a step ahead and ventured into the food hospitality sector where apps like Zomato and Swiggy scored big. Real Estate got itself MagicBricks.com. Manufacturing companies like Patanjali and SMEs like Tijori Ayurvedic Skincare also have their own websites to sell their goods.

Embracing digital technologies generates revenue.

They save costs and time. Documents are stored in digital format and stored in the cloud, optimizing expenses. There is less office space required and stationery costs are reduced. Printing, sorting, filing requires tons of billable working hours and enhances the cost of the product. Companies like TranZact are helping SMEs achieve this by providing an easy platform for them to digitize their business

Read more on Ways to Help Your Team (& Yourself) Keep Up with the Digital Transformation.

Performance and productivity improvement happens on a massive scale. All critical data is now available in real-time on a mobile device, where the company and its employees can access it any time from virtually everywhere. This information could be anything ranging from comprehensive financial information on stock quotes, market data, communication with customers in an efficient way, and up to field workers able to communicate all the changes right away.

Security of company data

There are countless vulnerability issues when working with physical documents. Sophisticated modern security restrictions to protect data really work well throughout all the industries globally.

THE VALUE THAT PRESENCE OF DIGITALIZATION BRINGS:

The advantages that digitalization brings with it are humungous to say the least.

They help transcend geographical boundaries

Earlier a store opened in a place catered to the needs of that locality. Multiple stores required huge manpower. But today it is not so. Now products get a global reach, they can be accessed and processed anywhere irrespective of location. The offerings are extended to any Internet user, no matter the region of the country. Having access to warehouses at places and people to manage them can transform businesses. For example, Vinod Cookware was initially confined to areas in Mumbai and Palghar where their factory is situated. Their presence in stores was strong but after listing themselves on e-commerce sites, their revenue has multiplied manifold. A very good example of this can also be Bangalore-based hyperlocal delivery platform Dunzo which is helping neighborhood stores and grocery shops in going digital by providing them with a platform for E-commerce logistics by offering online delivery support, live tracking, and API integration.

It also helps team members to communicate & collaborate easily as all the documents are on cloud. This also reduces the paperwork usually required by teams

Here ar 5 benefits of digital documentation for SMEs.

Value addition for our customer

Apps by small businesses can be highly customized. Customers get filters that help them lead to their desired products with just a few clicks. There is a presence of reviews and rating system which helps other customers in their future purchases. For example, themessycorner.in which started as a place to buy personalized travel accessories has its own fan base now all over the nation. This process has made manufacturers get direct, true, and invaluable feedback which aids them in their progress. Unlike in the analog world, now the entire feedback mechanism has been condensed to a minute process which is cost-effective. It also gives a better customer service experience and forges better relationships.

Another way to deliver value is by giving the consumers products that are customized to their whims. This level of personalization in a traditional factory set-up is not possible.

It helps increase sales:

Before digitalization came in, door to door sales was conducted, apart from contracting vendors and opening stores. This whole exercise was extremely labor-intensive. Now, Marketing Automation Tools (MAT) is a boon in this regard in Digital India. When a company uses this, they not only sell their products because of the website, they are able to capture customer behavior and monetize its courtesy MAT to increase their sales.

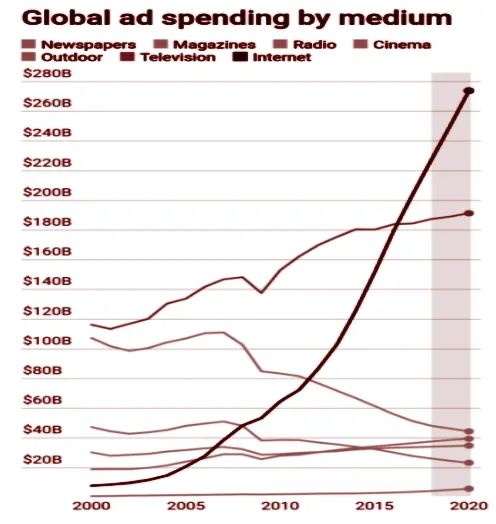

It eases marketing

Fliers, newspapers, and TV were sources of marketing. This presented a lack of certainty. A prospective customer may or may not see the flier. They may or may not read the newspaper on the particular day(s) you advertise or watch TV. But now, if one is able to accurately guess the digital footprint of their target audience, then marketing becomes so much easier. Placing advertisements using Pay Per Click, Google Ads, Google My Business help enhance the visibility of one's product.

The single and biggest 'blind spot' in marketing prior to digital transformation was the lack of high-quality data for marketing experts to make decisions. The performance of a television ad or print ad collateral could never be judged. How many people saw that subway poster? How many people watched the commercial on television? what age group is liking the product or service most, let alone went out and bought the product strictly because of it? Thus Analytics was a game-changer for marketing and digital transformation continues to emphasize just how useful it is going to be in all future marketing efforts.

It helps in the creation of a Brand

It's not possible to regularly interact and give personalized offerings and incentives to all the customers when one is not a part of the digital world. Gyan Dairy was able to achieve that by introducing their app. They offered incentives and cashback to their customers and have placed an effective communication system with them. This is very helpful in forging brand loyalty. Their goal was to challenge the supremacy of Amul in the dairy sector. Today they have managed to give people an alternative to Amul. In the long run, they might even compete with Amul.

Social Engagement that involves information sharing

An average person spends 2.4 hours on social media. If a business has an active social media handle, it helps in increasing product visibility. They also get to engage with consumers on a one-to-one level through podcasts, webinars, and social media posts. Thus digital transformation gives an opportunity to showcase their products and educate their customers at the same time. With so many advantages and opportunities in the offing, it's important to capitalize on it. It's important to do this quickly to create a niche for yourself in your chosen field. It's a race where you have to participate. The good thing is one doesn't necessarily have to win it, participation is more than enough.

One could talk about the wonders of digitalization all the time. How it quickens processes, enhances connectivity, and access leading to building meaningful relationships is something which we have been hearing for a long time. One may ask if there's any concrete proof of the same?

The proof is in numbers which have changed so dramatically.

We are aware of how the titans in the business world today were once small businesses themselves. Companies like Amazon, Flipkart, Facebook, Netflix all acted by hitting the iron when it was hot. They spurred themselves and became unparalleled global leaders in their fields to the point of affecting even further digital penetration.

- In 2007, 94% of the world's information storage capacity was digital. This was a complete reversal from 1986 when 99.2% of all storage capacity was analog.

- Itunes sold more music than Walmart in 2008.

- Amazon.com sold more Kindle books than print books in 2011

- In December 2012, annual e-commerce sales top $1 trillion worldwide for the first time.

- In 2017, online advertising (203.59 UDS) surpassed TV advertising (184.46 USD) worldwide. It had already done so for newspaper advertising in 2012

- Since 2008, there has been a decline of almost 86% courtesy of digital platforms like Netflix, HBO, Hotstar, and whatnot.

- As of April 2020, the global digital population is 4.66 billion.

By going digital not only they have managed to alter the consumer consumption patterns but in doing so, have created entire business domains for themselves. This has created certain realities that can no longer be ignored. Therefore, to stay relevant, SMEs must move towards accepting digitalization.

Way Forward In Digital India

Technological change is nothing new-but this round of change is happening at a rate faster than ever before. Some executives cite this transformation as 'disruptive technologies'; that risk is certainly real.

But if one does not evolve with the world, they are likely to be left behind. While new technologies may threaten established businesses, they can also create unprecedented opportunities.

An increasing number of executives are more concerned with missing opportunities to grow. It is not digital disruption that is impelling companies to change, it is digital "FOMO" (Fear Of Missing Out).

Being bombarded with such diverse options from all sides can be overwhelming. This is why the primary goal should be to enforce digital transformation with a clear cut vision. The strategy should lead to innovation.

The entire nation has joined hands to make the dream of a Digital India into a reality. Youngsters are enthusiastic, industry is supportive and the government is proactive. India is yearning for a digital revolution.