A procurement process is the pillar of success for a manufacturing business. The structure and flow of a procurement business process vary on the size and complexity of the purchase, purchase policies, and organizational procedures.

With an effective direct and indirect procurement process flow, a business can leverage structured methods to simplify its purchase and sourcing activities. This helps to reduce time, save costs, and build effective supplier relationships.

After reading this blog, you will understand all about the procurement process, including procurement process steps, types of procurement, procurement tools, and more.

What Is Procurement?

Procurement involves sourcing and acquiring goods or services to meet an organization's needs. It encompasses identifying requirements, finding suppliers, negotiating terms, and making purchases.

Procurement can include a wide range of activities, including sourcing and selecting suppliers, negotiating contracts, and managing the delivery and payment process. Procurement is an important function in any organization because it helps to ensure that the necessary resources are available to support the organization's overall operations.

In essence, the term ‘procurement’ denotes the final act of purchasing and is commonly associated with all businesses that are directly or indirectly involved with the purchase of goods for business growth.

Read Also - What Is Inventory Management? Types, Benefits and Techniques Explained

What Is a Procurement Process?

A procurement process is a series of processes to acquire services or products, from requisition and

purchase orders

to invoice approval. Procurement in the

manufacturing industry

lies at the start of every business activity. Ultimately, it contributes to the business's strategic and long-term goal-achievement process.

A procurement process is a series of processes to acquire services or products, from requisition and

purchase orders

to invoice approval. Procurement in the

manufacturing industry

lies at the start of every business activity. Ultimately, it contributes to the business's strategic and long-term goal-achievement process.

Procurement process optimization comprises 3Ps - Process, Paperwork, and People.

- Process

This function entails the list of rules to be followed while ordering, reviewing, paying for, and obtaining goods and services. The procurement process steps are subject to increase with the purchase complexity.

- Paperwork

It refers to the paperwork and documentation that are required at each stage of the procurement process flow. These are collected and preserved for auditing reasons when it comes to monitoring the business procurement process.

- People

These refer to the stakeholders and their responsibility in the procurement cycle. The risk and value involved in any purchase are directly proportional to the number of people or stakeholders and their respective activities.

Read Also - What Is Proforma Invoice

Why Is Procurement Important in Business?

Procurement plays a pivotal role in the operational efficiency and strategic development of a business. Here’s why it’s indispensable:

- Reliable Supplier Sourcing: It aids in finding trustworthy suppliers, ensuring that businesses can acquire goods and services at the most favourable prices.

- Quality Consistency: Procurement ensures consistent quality in products and services, contributing to smoother product development processes.

- Business Opportunities and Relationships: It opens doors to new business opportunities and helps in maintaining robust relationships with existing suppliers.

- Risk Mitigation: By outlining clear procurement steps, businesses can select suppliers with proven reliability, minimizing risks associated with unreliable deliveries.

- Cost and Time Savings: A well-structured procurement process helps companies avoid inefficient suppliers, leading to significant savings in both money and time.

- Operational Efficiency: Streamlining the procurement process reduces lead times and enhances overall operational efficiency.

- Regulatory Compliance: It ensures that the organization stays in compliance with statutory regulations related to the acquisition of goods and components.

Read Also - Best Bill of Materials Software in 2023

How Procurement Works?

Procurement procedures are generally dictated by company standards which are consolidated by controls from the accounts payable teams. Direct and indirect procurement process flow can include operations such as preparation, demand processing, payment approval, and receipt. In general, the procurement business process involves identifying the need for the goods or services, selecting a supplier, negotiating purchase terms, and placing an order. It may include the following details for seamless processing -

- Standards

- Purchase request and planning

- Supplier research

- Specifications

- Financing

- Price negotiation

The sourcing and procurement process can be done by an organization to meet its internal needs, or it can be done on behalf of a client.

An effective procurement strategy impacts the broader management strategy of a business, as the ability to purchase services and materials seamlessly can determine the profitability of the operations.

Complex businesses such as small and medium manufacturers need integrated systems to manage procurement successfully. This is because procurement is interconnected with demand forecasts, sales numbers, and inventory levels.

Types of Procurement Process

The process of procuring goods and services for a business should be considered a strategic decision that will ultimately drive quality product deliveries to customers.

The process of procuring goods and services for a business should be considered a strategic decision that will ultimately drive quality product deliveries to customers.

Procurement in the manufacturing industry can be of different types and it can be categorized based on how the business entity will use the procured items. Following are some key procurement types to know about:

- Direct procurement

It is the process of obtaining a product required for producing another product. In the case of a manufacturing company, this can include procurement of raw components and materials for the production of final goods. In the case of retailers, they buy these items from a wholesaler for resale to the customers.

- Indirect procurement

This type of procurement involves purchasing products that are mandatory for everyday operations but do not directly affect the business' bottom line. This includes everything from office furniture and supplies to consulting services, advertising campaigns, and equipment maintenance.

- Goods procurement

It refers to the procurement of physical items as well as other non-physical ones like software subscriptions. An efficient goods procurement workflow can rely on good supply chain management, including indirect and direct procurement.

- Services procurement

It is dedicated to procuring people-based services. This can include hiring contingent labor, individual contractors, on-site security services, or law firms. This can also include both direct and indirect procurement.

Read Also - Purchase Order: Definition, Process, and How to Create

Steps in the Procurement Process

The beginning of an effective procurement process starts with planning, followed by other important steps. These steps are also crucial to incorporate when it comes to implementing software procurement best practices.

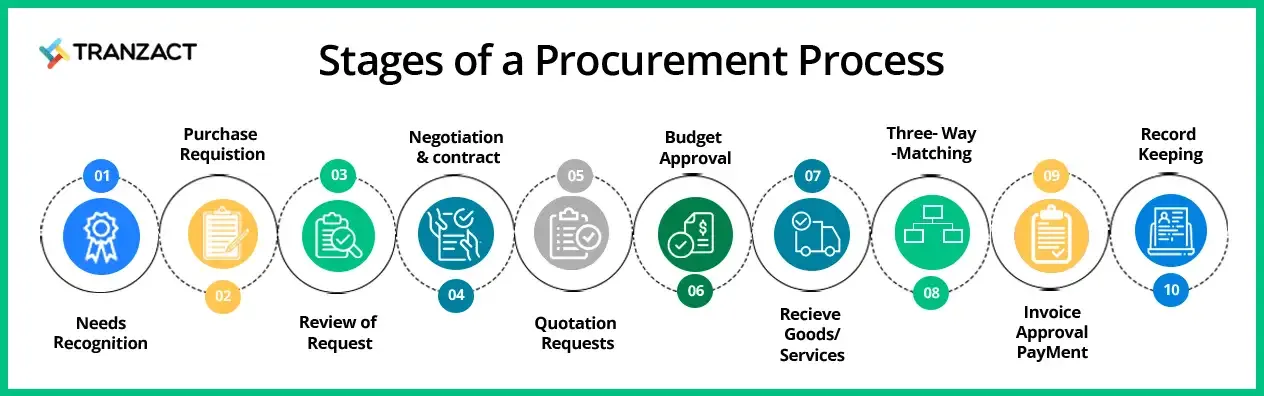

Following are ten steps of the procurement process that will help you to streamline your procurement functions -

1. Recognize company needs

The first step of procurement is recognition. In this phase, a business starts researching and planning for how goods and services can be procured at a low cost, and on time.

2. Submit a purchase request

In this step, you need to create a purchase requisition where written permission to make the expense is given. The staff uses this internal document to request the services and goods needed for completing the job. It contains all the necessary details for approval, such as -

- Quantity

- Product

- Name of requester

- Price

- Department

In addition to this, a purchase request must include all necessary data to fulfill the existing order.

3. Review requisition package

The official procedure starts after the approval of the purchase requisition and completion of a cross-check for budget availability. In this stage, the department heads alongside the manager review the requisition package.

They ensure that the requested need is genuine and verify the availability of the funding. Approved requisition request turns into a purchase order (PO) while the rejected requests are sent back to the requisitioner with a valid reason for rejection.

4. Solicit best suppliers

After PO generation, a procurement plan and a solicitation process are developed by the procurement team. The scope of the procurement plan depends upon the requirement's complexity.

After budget approval, a Request for Quotation (RFQ) is forwarded to the vendors to receive and compare bids and select the best suppliers.

5. Review and evaluate suppliers' performance

After closing the solicitation process, the team reviews and evaluates the referrals, supplier performance, and quotes to understand the best fit and price.

6. Negotiate a contract

Contract negotiation starts after vendor selection, and a PO is forwarded to them. A PO is a legally binding contract that activates as soon as the vendor accepts and acknowledges the purchase order.

7. Manage orders

The vendor delivers the services and goods within a specific timeframe. After receiving, the buyer examines the order and notifies the vendor if there's any issue with the received goods.

8. Conduct two or three-way PO matching

Before sending for approval, the supplier's invoice should be validated. Traditionally, the accounts payable staff searches for POs, receipts, and other paperwork and attaches that to the invoice. However, with automated procurement processes, companies can streamline the complete documentation procedure. The PO, invoice, and receipt are compared via a three-way match to identify any discrepancies. After matching, the invoice is sent for approval.

9. Approve or dispute invoices

Internal approvers review all the documentation and sign off on payment. The invoice will then be forwarded to payment processing.

10 Keep records

After sending all payments, the company accounts for the transaction. For easy auditing and bookkeeping purposes, records and documents must be stored in a centralized location.

Read Also - Inventory Management in MS Excel: Everything You Need to Know

Stages of Procurement

The above-mentioned steps can also be categorized into three distinct stages: the sourcing stage, purchasing stage, and receiving stage.

- Sourcing stage

This stage covers the initial stage of identifying business needs, creating purchase requests, and assessing vendors. After the initial sourcing steps are completed, building a strong relationship with the suppliers is necessary. They can prepare grounds for the suppliers to improve products, learn from partners and develop trust.

- Purchasing stage

It includes negotiation terms, order creation, receiving, and inspection of goods and services.

- Payment stage

Accounts payable initiates accurate validations to ensure invoice and order correctness. The invoice is then approved, and the payment is made. Records of orders, invoices, and payments must be carefully maintained.

Procurement Life Cycle

The procurement life cycle is a critical component of material management, tailored to meet the unique needs of each business. Here’s a breakdown of its key stages:

- Assess Procurement Needs: Begin by thoroughly evaluating the business’s demand to accurately determine procurement requirements.

- Identify Potential Suppliers: Search for potential suppliers capable of meeting these needs.

- Conduct Competitive Bidding: Engage in a competitive bidding process, evaluating suppliers based on quality, price, delivery schedule, and past performance.

- Select a Supplier: Choose a supplier that best fits the business’s criteria and requirements.

- Agree on Purchase Terms: Negotiate and agree upon the terms of purchase with the selected supplier.

- Place the Order: Officially place the order for the required goods or services.

- Process the Order: The supplier processes the order, preparing the goods or services for delivery.

- Evaluate Delivered Goods: Upon delivery, evaluate the products to ensure they meet the established requirements and quality standards.

- Payment or Rectification: If the goods meet the standards, proceed with payment as per the agreement terms. If not, communicate the discrepancies to the supplier for rectification.By following these stages, businesses can optimize their procurement processes, ensuring they acquire the right products at the right price while maintaining quality and efficiency.

Read Also - 5 Best Inventory Management Tools You Need

How to Optimize the Procurement Process?

The procurement lifecycle can become complex as it involves a lot of parties and necessitates several cumbersome steps. Many different and sometimes conflicting goals need to be addressed across stages. A streamlined procurement process can facilitate better control over each stage of the procurement lifecycle. Below are some steps to follow to optimize your procurement process.

- Invest in a good procurement solution

- Define a clear procurement strategy

- Enable seamless employee adoption with training

- Create a convenient communication platform with suppliers

- Determine costs and plan according to the company budgets

- Establish policy and process compliance

Procurement, Purchasing, and Supply Chain: Get to Know the Difference

The terms purchasing, supply chain, sourcing, and procurement may sound and reference similar meanings in some scenarios. However, there are some distinctions between all of them. Let's understand them in detail:

- Procurement vs Purchasing

Purchasing refers to buy transactions and only focuses on managing specific purchase orders to cater to the company's needs. Procurement, however, is a broader and more complex process that also extends to establishing and maintaining supplier relationships. Procurement comprises a proactive approach that includes analyzing company needs, while purchasing has a reactive approach, focusing on obtaining what the business has already decided it needs.

- Procurement vs Sourcing

Sourcing is only part of the procurement process. It is a primary stage of the procurement cycle which involves activities like identifying and checking the services of potential suppliers, negotiating conditions, and selecting the vendors that are the best fit for the company. The sourcing stage of the procurement process is one of the most important ones, as it's here that potential vendors are identified, and compared, and their qualifications are checked. This stage also validates the performance history of the potential suppliers.

- Procurement vs Supply Chain

Procurement covers a definite aspect of supply chain management. It includes obtaining, paying for, and sourcing services and goods. There are various sources to procure materials for manufacturing goods, and procurement is responsible to identify the best source suited to provide these items. Supply chain management covers end-to-end operations dealing with obtaining goods, such as managing warehouses and shipping, transforming the procured items into finished products, and distributing those to consumers.

Principles of Procurement

The geographic scope of procurement for businesses may depend on their operational size. Large companies may choose to outsource all their procurement needs for ease of operations, but small businesses may choose to restrict their procurement to local purchases if they don't want to deal with excessive middlemen.

Based on this, the procurement principles for a business vary, but in general, they are identified as follows:

- Value for money

The procurement team must efficiently and economically manage funds while procuring services and goods. It might need to run risk assessments and cost-benefit analyses. Factors like durability and quality also need to be considered while determining if the purchase is worth the money.

- Fairness

All procurement bids must be objectively assessed based on their ability to meet company needs.

- Efficiency

The entire process must be set up in a way that maximizes value and avoids any delays efficiently.

- Competition

Businesses should look for competitive bids from numerous suppliers unless there is a sole-source provider, wherein only a single vendor provides a specific service or product.

- Transparency

Procurement teams should ensure everyone, including suppliers and internal stakeholders, have access to relevant details. It can be kept confidential only in case of legal grounds.

- Integrity

While all procurement operations must be done with integrity, the ones involving public procurement have a greater responsibility to be reliable, and honest. Public funds should be used only for the public interest and the intended purpose. All procurement procedures are obliged to report accurate activity reports, including errors.

Read Also - What Is Vendor Managed Inventory?

Procurement Best Practices

Here are some best practices to organize your procurement cycle:

- Automate procurement processes

By automating procurement processes, manufacturing businesses can prevent bottlenecks and disruptions. This helps to save time, reduce human error like miscalculations and misentered order numbers, and decreases processing costs.

- Adopt well-defined processes

Well-defined purchase processes help to prioritize activities. To create a well-defined procurement process, document each step of the purchasing procedure, identify the person responsible for each task, and outline the process of performing those actions step-by-step.

- Practice process transparency

Transparent purchase processes enable faster processing, higher accountability, and responsible sourcing practices.

- Centralized contract and documentation hub

Most procurement contract complications come from not having a centralized platform for documentation. Having streamlined documentation, including operational processes and contract templates, ensures fewer errors, and consistency of communication, and ensures time is not wasted in dealing with remedial work.

- Use data to optimize inventory

Since procurement is directly related to inventory, it's important to ensure stock optimization with the help of accurate data. This helps to reduce scenarios of excessive stock which leads to low logistics fees. It also helps to determine if there isn't enough stock, as it may lead to delays in meeting customer demands.

- Multi-sourcing procurement strategy

Many successful organizations multi-source their products to reduce reliance on one supplier as it can create resilience and avoid sudden delays in the procurement systems.

- Strong supplier relationships

Building strong supplier relationships ensures that you can easily deal with potential bottlenecks before they can become crisis points. The supplier informs you about issues ahead of time, and you can also keep them informed about payment problems or process alterations.

Software procurement best practices are similar to the above; these guidelines can also help your business when you want to procure new software.

Adopt a Procurement System by TranZact

To ensure that your procurement system runs seamlessly, you will need well-defined and automated procurement solutions. TranZact is a business digitization software that offers expert procurement solutions for your SME manufacturing business.

It is integrated with sales, purchases, and inventory functions and therefore, helps to optimize operations, increase transparency and digitize procurement workflows with a few clicks only. With TranZact, you can streamline supplier relationships and ensure that your business has all the required material in time for production. It supports your procurement teams to centralize all necessary documentation with adequate record-keeping. All of this is enabled over a cloud platform for exceptional business ease.

FAQs on Procurement Process

1. What are the 10 steps of procurement?

The ten steps of the procurement process include recognizing company needs, submitting a purchase request, reviewing the requisition package, and soliciting the best suppliers. This is followed by reviewing and evaluating suppliers' performance, negotiating a contract, managing orders, and conducting two or three-way PO matching. The final steps are approving or disputing invoices, and keeping records for auditing and bookkeeping purposes.

2. What are the 3 stages of procurement?

The 3 stages of procurement are the sourcing stage, purchasing stage, and payment stage. Properly managing each stage is crucial for achieving cost savings, mitigating risks, and maintaining a smooth and reliable supply chain.

3. What are the 4 types of procurement?

The 4 main types of procurement are direct procurement, indirect procurement, goods procurement, and services procurement. Strategic procurement and tactical procurement are the secondary types of procurement relating to long-term and short-term business needs.

4. How is sourcing different from procurement?

Sourcing refers to the activity of identifying potential suppliers for goods needed by an organization. Procurement, on the other hand, refers to the larger process of acquiring goods from external suppliers, including activities such as negotiating contracts, placing orders, and managing the payment process.

In other words, procurement is the broader term that includes sourcing as one of its components.

5. What are the benefits of the procurement process?

Procurement is an important part of many organizations, as it helps to ensure that the necessary goods and services are acquired in a cost-effective and convenient manner.

An end-to-end procurement process supports an organization to identify and select reliable suppliers that can provide high-quality goods, catering to the company's needs. This leads to an overall increase in operational efficiency and customer satisfaction for the business.

6. What is procurement software?

Procurement software is a computerized program that assists organizations to automate all their procurement activities including sourcing, purchasing, and vendor management.

7. How to improve the procurement management process?

The best way to improve procurement management processes is to go digital and upgrade procurement documentation and validation with an automated solution. It's also important to regularly evaluate supplier performance to ensure that they are meeting the organization's expectations and to identify any potential issues well in advance.

8. What is the golden rule of procurement?

The golden rule of procurement is to define clear objectives and priorities and share the same with all involved teams. It's crucial for everyone in the organization to have a clear understanding of the organization's needs and goals in order to effectively manage the procurement process in the long term.