Accuracy, productivity, and flexibility are key factors in the automotive manufacturing sector. How the auto component industry uses ERP systems can help them perform successfully in the current market. When it comes to the success and growth of the auto component sectors, these advanced solutions are more than just technological tools; they are the heart of the industry.

In this article, we will explore everything about ERP for the Auto Components Industry and how it helps with the smooth running of all operations. In addition, we will also see how it helps in the management of complex supply networks.

What is ERP for the Auto Component Industry?

Enterprise Resource Planning or ERP for Auto components industry is important for smooth operations in the automotive sector. It allows for in-depth research, design, and development in line with client demands.

ERP software manages regular manufacturing processes, improves inventory management, offers insightful reports, and makes sure of on-time deliveries. In short, the ERP for the auto component industry is the main force behind improving production, increasing customer satisfaction, and supporting the success of the auto component sector.

What are the Major Challenges in the Auto Components Industry?

Even though the role of ERP in the Auto Component Industry is important, its operations must continue to grow and improve to survive in the market. Here are some key issues in the automotive components industry:

1. Rising Commodity Prices

The ongoing rise in raw material and commodity prices directly affects India's automotive sector. As a result of rising consumer demand, car prices rise, forcing foreign investors to manage production costs properly.

2. Skills Gap

Due to quick technical improvements, auto component manufacturing companies must provide regular personnel training. Unfortunately, the shortage of training resources adds pressure on manufacturers attempting to meet the nation's auto parts demand.

3. Changing Regulations

Strict emission control requirements imposed by the government to reduce air pollution and global warming present a major challenge. Balancing increased fuel usage, keeping up with the most recent emission requirements, and reducing costs proves to be difficult. The growing popularity of electric automobiles adds another degree of challenge.

4. Semiconductor Shortages

Global semiconductor shortages greatly impact Indian vehicle sales, directly affecting auto component manufacturing. Because of the shortage, passenger vehicle sales have dropped by 14% in the current fiscal year.

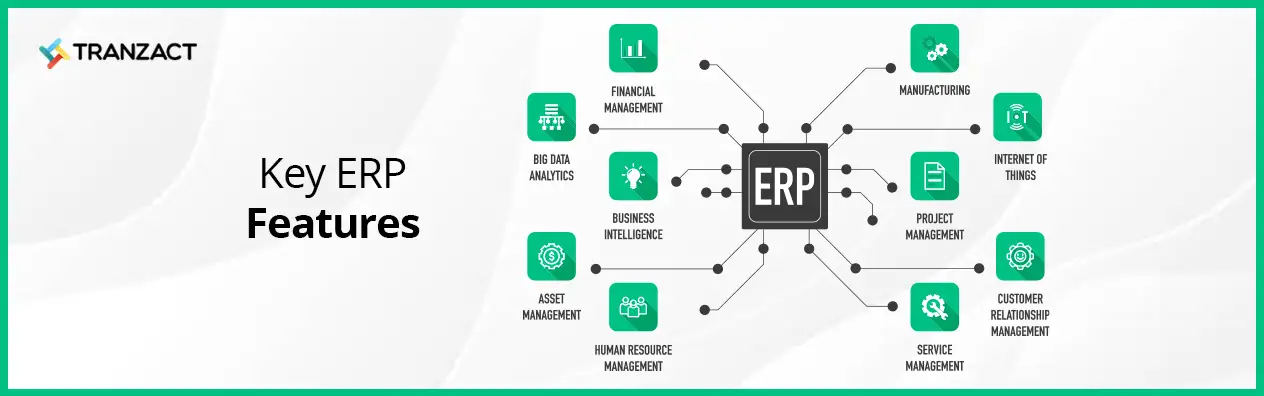

Features of ERP for Auto Components Manufacturing

The best ERP for Auto component industry offers many key features, some of which are:

- Helps control your organization's money-related areas, like budgeting, spending, and revenue, to keep your finances in order.

- Helps plan, organize, and control the flow of materials and completed commodities.

- Using the customer relationship management feature, you can always remember your customers and their preferences to satisfy them.

- The inventory management feature allows you to keep tabs on your goods and supplies so you never run out of anything.

Key Benefits of Automotive ERP

Here are the key Benefits of Automotive Enterprise Resource Planning:

1. Track User Preferences

Automotive ERP software like TranZact keeps track of customers' orders and preferences. It helps in the development of products that customers are more likely to purchase by studying previous purchases and preferences.

2. Improved Cooperation

ERP software in the automotive industry provides real-time data and easy-to-access databases, improving security and promoting team cooperation. Quick data sharing increases a business’s overall productivity.

3. Cost Savings

Automotive ERP combines multiple software systems across several business divisions. Finance, product development, and customer relationship management are all combined into a single interface. It improves processes, increases ROI (return on investment), and keeps manufacturers on track with laws while remaining competitive.

4. Simplified Inventory Levels

ERP software helps in inventory tracking and ordering items as needed. This prevents auto component shortages that can cause decreased sales and productivity. The tool also assists in keeping track of the expiration dates of stored products.

Learn How to Use ERP for Auto Components Manufacturing Businesses With TranZact

The role of ERP in the Automobile industry is important for maintaining the smooth running of auto component manufacturing businesses. It simplifies key components, including finance management, supply chain coordination, customer connections, and inventory control. Tranzact’s ERP software helps manage difficulties faced by the auto components business, such as rising costs, skills gaps, changing regulations, and semiconductor shortages. Our ERP systems help Indian SMEs to overcome these challenges.

FAQs on ERP for Auto Components Manufacturing Companies

Q1. What are the ERP Advantages in the Manufacturing Industry?

ERP makes production, sales, purchasing, and inventory plans more logical. Based on historical transactions, it allows you to develop forecasts and sales reports. This prevents difficulties by reducing out-of-stock or surplus inventories.

Q2. How can ERP help with tracking in the manufacturing of auto components?

ERP keeps detailed records of components, their origins, and production history. This function helps track the sources of any defective parts, allowing for quick recalls and preventing quality concerns from affecting the entire supply chain.

Q3. How can small auto component manufacturers benefit from ERP?

ERP gives small auto component manufacturing companies greater control over their operations, allowing for better inventory management, cost savings, and improved processes. It also promotes sticking to industry standards, which improves overall productivity and performance.

Q4. Can ERP help with quality control in car component manufacturing?

Absolutely. Quality control modules are frequently found in ERP systems, allowing auto component makers to check quality at each manufacturing stage. This guarantees that customers receive only high-quality components, reducing faults and rework.

Q5. What cyber security protections are used to protect sensitive data in ERP for Auto Component Company?

Leading ERP solutions use strong cybersecurity protections such as data security, access limits, and frequent software updates. These measures help protect sensitive firm data and prevent unwanted access.

Q6. Can ERP be combined with other software in the automotive component manufacturing company?

Yes, many ERP systems include connectivity, allowing you to link with other software, such as CAD (Computer-Aided Design) tools, production planning software, and CRM (Customer Relationship Management) systems, for seamless data sharing and workflow management.