The vendor-managed inventory (VMI) approach provides manufacturers and vendors with real-time visibility into inventory levels and consumer trends. This enables them to proactively adjust production and replenishment strategies to meet changing demand patterns efficiently and effectively.

If you are considering getting into a VMI contract, you must first understand the meaning of a vendor-managed inventory system and how it works.

This guide on vendor-managed inventory will support you in knowing more about vendor-managed inventory benefits, along with its challenges, and the role of vendor-management inventory software. So, let's begin.

What Is Vendor-Managed Inventory?

Vendor-managed inventory is an inventory management system that optimizes supply chain functionality by streamlining a collaborative and direct data-optimizing relationship between the manufacturer, supplier, dealer, and customer.

VMI enables auto share and data integration facility which allows supply chain partners to integrate an efficient smart and demand-driven supply chain with easy-to-access inventory information. Business functionality, particularly supply chain planning benefits from improved stock management, product demand, and requirement.

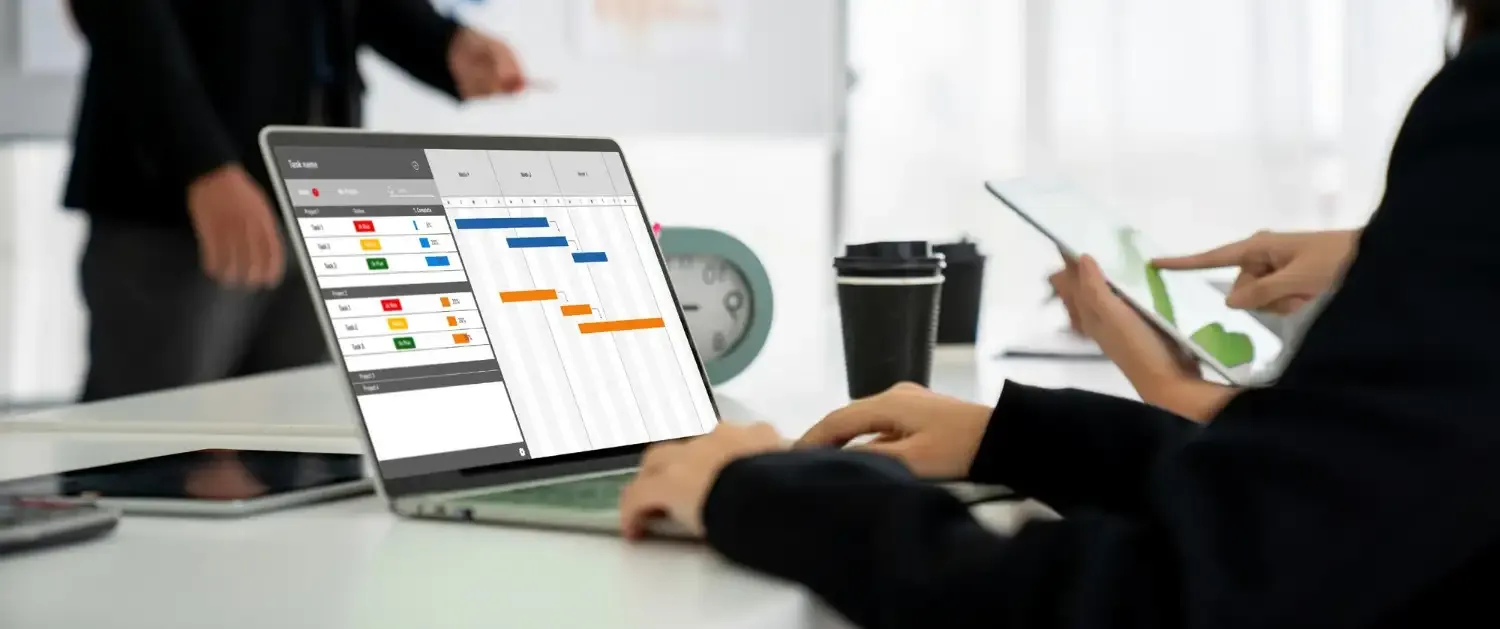

Vendor-Managed Software System

A vendor-managed software system is an automated software that enables direct collaboration between suppliers and distribution partners by streamlining essential inventory data like stock, market demand, daily deliveries, stocks sold, stocks outdated, and more.

Since data accuracy is sincerely managed by vendor-managed inventory software, it results in minimized errors and reworks. This further results in saving time, enhanced revenue, improved in-stock percentages, heightened sales, reliable inventory turns and filling, and creates a guard against supply chain disruption.

Read Also - ABC Analysis in Inventory Management: Benefits, and Implementation Strategies

How Does Vendor-Managed Inventory Work

Vendor-managed inventory solution is designed to offer combined data to enhance supply chain performance by stringing in demand forecast data as well as point of sale (POS) data from consumers and suppliers.

Here's how it works:

- The VMI system receives a Product Activity Report from a distribution partner with comprehensive analytical data on sales figures, products in shelf presence, products in transit, inventory targets, and position.

- The VMI platform analyses the data and considers key objectives, market factors, and products in supply to create an inventory replenishment order.

- These recommendations are then thoroughly studied, reviewed, and finally approved by the supplier and VMI system or the vendor-management inventory software to generate a recommended Purchase Order (PO).

- On approval from a supplier, the VMI sends the PO to the distribution partner via an electronic data interface (EDI) format.

- The distributor partner or channels approve the PO for processing to the supplier.

Next, let's read about vendor-managed inventory benefits in detail.

Read Also - Best ERP Software for Manufacturers in 2023

Benefits of Vendor-Managed Inventory

Choosing vendor-managed inventory solutions or collaborative systems are strategic investments to push the lines of improved implementation of a productive supply chain.

It is a comprehensive system linking and facilitating distributors, suppliers, consumers as well as retailers by improving key experiences. The benefits of a vendor-managed inventory system are as follows:

Cost savings and increased efficiency

Vendor-managed stock enables accurate purchase order designing for approval and processing. It minimizes labor costing, saves time, and integrates improved inventory management. It helps to create easy forecasting-ready records of the customers' POS data, leading to improved and superior service levels for consumers with the availability of the right products all the time.

Reduced lead times

Vendor-managed inventory software supports your business to reduce lead times and increase revenues and sales by eliminating scopes of stockouts, estimating the shelf life of products, and managing product assortments seamlessly. Further, it helps to minimize returns and wrong orders with accurate stock data, and fast, improved inventory stocking.

Read Also - Inventory Optimization: Process, Techniques and Challenges

Improved inventory accuracy and reduced stockouts

Distributors and suppliers can essentially minimize off-guard emergencies like stockouts, limited stocks, limited variety, and missed sales with vendor-managed stock. Moreover, businesses can increase inventory turns and cut the carrying costs of inventory. This reduces duplicate orders, emergency supply needs, and returns, thereby, enhancing operational efficiency.

Enhanced collaboration and communication between vendors and customers

With vendor-managed inventory, businesses can achieve improved supply chain planning and relationships between distribution partners. They can also ensure improved customer satisfaction and experience by maintaining optimal product stock levels and having the required products readily available in inventory to meet customer demands.

Challenges and Limitations of Vendor-Managed Inventory

Even though a superior and reliable inventory management system is the need of the hour, there are a few limitations of vendor-managed inventory that you must be aware of.

Resistance to change

Very often, suppliers like to have comprehensive control over their inventory and that's why they may be resistant to change. However, when integrating vendor-managed inventory solutions, you essentially need to share your inventory data with a third-party vendor. To let go of the control, they need to be sure about the exceptional abilities of the vendor in managing inventory accurately and reliably.

Complex implementation process

Not every supplier may have an assorted supply of products as inventory. Besides, getting into a vendor-managed inventory contract is like a direct partnership with a supplier. Now that supplier might not be suitable due to poor services, limited supply or a variety of products, delay in offering supplies, or any other reason. This may lead to supply chain disruption.

Limited market responsiveness

If you feel you have better control over your business owing to your exclusive market forecasting abilities, then handing your inventory management to a third party will reduce your market responsiveness.

With a third-party vendor managing your inventory data via traditional systems, there are chances that you might not get an alert regarding sales forecasts and as a result, miss productive sales opportunities.

Read Also - What Is Barcode Inventory System?

Best Practices for Implementing Vendor-Managed Inventory System

If you follow the best practices of vendor-managed stock and build a strong, reliable, and steady relationship with your vendor, you are unlikely to face any significant concerns. Some best practices for implementing a vendor-managed inventory system that will help are:

Choosing the right vendor

By asking the right questions you can certainly choose the right VMI provider, but for this, you must be aware of the questions to ask. These include price models, previous experience and reviews of the vendor, range of products, flexibility of the VMI platform, customization, and customer support.

Do ask if they have any regular performance tracking and analysis features. Check out if your VMI provider offers custom setting options to upgrade essential requirements with time. If it's your first time with a vendor for a VMI agreement, make sure to enter into a short-duration partnership. Most importantly, you must have the skill to negotiate the deal with the vendor before entering an upfront VMI system.

Establishing strong communication channels

To promote customer satisfaction and enhance inventory management, real-time communication is a useful tool. Vendor-managed inventory software can help to guard against demand fluctuations, poor market forecasting, and dissatisfied customers.

You can keep customers informed about special occasions, seasonal supplies, products on offer, and so on. Inform your vendor, immediately whenever you find a certain product sale has dropped or when there is demand for a new product.

Defining clear roles and responsibilities

A successful VMI relationship requires buyers and sellers to discuss their requirements, roles, and responsibilities openly. Know your expectations from a vendor-managed inventory and discuss them before entering into any VMI contract.

Why Choose Vendor-Managed Inventory?

Inventory management ensures inventory is never out of stock while ensuring production and customers' orders are fulfilled on time. Managing inventory levels on one's own is a cumbersome job. This is where vendor-managed inventory helps, especially if you are a manufacturer.

TranZact helps you with managing all your vendor relationships with simplified ease. You can automate PO creation, connect with suppliers and compare quotations effortlessly. This helps you to save time, and reduce procurement and stock-holding costs significantly.

FAQs on Vendor-Managed Inventory

1. What is vendor-managed inventory?

Vendor-managed inventory is a supply chain practice where the supplier or vendor takes responsibility for managing and replenishing inventory at the customer's location.

2. How does VMI work?

In VMI (vendor-managed inventory), the vendor or supplier monitors the customer's inventory levels, receives data on sales and inventory, and proactively restocks the inventory to ensure availability.

3. What are the challenges of implementing VMI?

Challenges of implementing vendor-managed inventory or VMI include difficulties in establishing trust and collaboration between the supplier and the buyer, sharing accurate sales and inventory data, and aligning strategies and goals.

4. Does VMI require special technology or software?

While vendor-managed inventory (VMI) can be implemented manually, it is often supported by specialized software or systems that facilitate data sharing and automate inventory replenishment.

5. How can I implement VMI in my business?

To implement VMI (vendor-managed inventory), businesses should start by identifying suitable suppliers, establishing clear communication channels, and defining performance metrics. Using these steps your business can gradually transition to the VMI model through a collaborative approach.

6. What is the purpose of VMI?

The purpose of vendor-managed inventory (VMI) is to shift the responsibility of inventory management and replenishment from the manufacturer or buyer to their suppliers. It aims to ensure optimal stock levels and availability while reducing inventory costs.

7. What companies use vendor-managed inventory?

Nowadays, not only large-scale organizations but even SMEs look up to vendor-managed inventory (VMI) as a business solution and investment. Companies use VMI solutions to benefit both demand and supply flow in an inventory.

8. When does VMI work best?

To make VMI (vendor-managed inventory) work well, the vendor and the supplier must be in sync. Information clarity, awareness of goals, fee management, and top-notch service by vendors along with a strong relationship between both parties are a must to make a VMI system work.