ERP for the pharmaceutical industry is used to centralize and coordinate their many different functions. ERP systems have become increasingly popular in the healthcare industry in recent years because of their promise to boost efficiency, save costs, and better serve patients.

Hospitals and other medical facilities may improve their operations and patient care with the help of ERP for the pharmaceutical industry. Generally speaking, the healthcare business is finding that investing in ERP technology is a wise decision that is improving efficiency.

In this article, we will cover the challenges in the pharmaceutical industry and the benefits of ERP for the pharmaceutical industry in depth.

What Is the Pharmaceutical Industry?

The pharmaceutical business is responsible for the research, development, and manufacturing of chemicals used in the treatment of diseases in people and animals. Its scope is broad and it involves several government agencies, laboratories, substances, and regulations.

The pharmaceutical industry is a complicated one with many moving parts, and we must be aware of all of them. The healthcare industry's ultimate goal is to eliminate patient health problems by developing and marketing effective pharmaceuticals, therapies, and remedies.

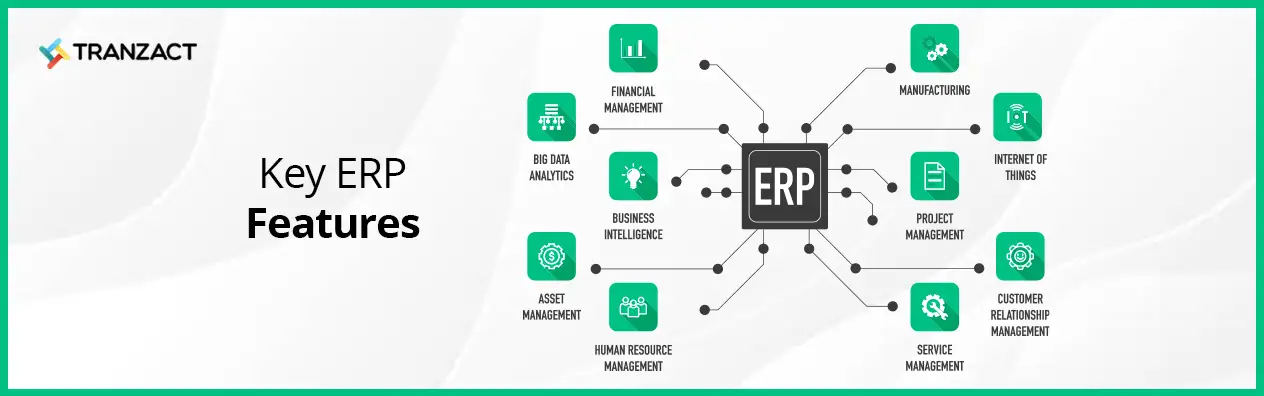

What Is ERP?

Enterprise Resource Planning (ERP) is a software that not only simplifies processes but also allows you to better manage day-to-day operations by coordinating end-to-end processes and tasks. Business operations, financials, and bookkeeping are all easier to keep track of with the help of an ERP system.

ERP is seen as essential by companies of all sizes, not just the big ones. ERP software, an integral part of everyday operations, productivity, and record-keeping, boosts efficiency and accuracy to save a lot of time and effort by reducing errors.

How Does ERP Help the Pharmaceutical Sector?

The following points highlight how an ERP solution for the pharmaceutical industry is beneficial:

Effective Budgeting and Planning

Budgets may be better managed with the aid of an ERP solution that provides real-time visibility into financial processes. Healthcare providers may save time and improve precision by automating their financial procedures. Budgeting, forecasting, and spending monitoring are all a part of it, as are accounts payable and receivable and the general ledger.

Better Management of the Supply Chain

Medical equipment and supplies may be kept on hand and ready for use with the help of an enterprise resource planning (ERP) solution's streamlined inventory management, procurement, and distribution processes. The high costs of running a hospital inventory are mitigated by this tool.

Improved Efficiency in the Purchasing System

An ERP solution guarantees quicker processing times and lower costs by integrating data from suppliers, purchase orders, vendors, receivers, and invoices into a single framework. Procuring products and services from preferred suppliers at cheaper pricing is made easier with real-time visibility.

Efficiency Gains in Business Operations

With an enterprise resource planning system in place, coordination across offices is simplified. Everything from patient check-in and check-out through appointment scheduling, payment, and test results is handled quickly and efficiently.

Managing for Compliance

Industry rules, such as security guidelines and government financing criteria, might be easier to meet with the help of an ERP solution. Integrated monitoring tools aid in keeping tabs on actions and swiftly notifying admins of any security breaches.

Care Enhancements for Patients

With all of a patient's health data in one place and quick retrieval made possible by reporting tools, doctors can obtain more insight into their patients' ailments. This enhances patient outcomes, including diagnosis, treatment, and medication management.

Why Do Pharmaceutical Manufacturing Businesses Need ERP?

There are several ways in which an enterprise resource planning system may improve the efficiency and productivity of pharmaceutical manufacturers. ERP software may help the pharmaceutical industry rebuild, make more informed demand projections, and better manage its finances.

They need a comprehensive answer that coordinates and simplifies the myriad departments and processes within a pharmaceutical unit. Pharmaceutical ERP software automates every crucial business operation, from product development to distribution to financing to inventory to quality control, so that companies can stay in compliance with regulations and uphold high-quality standards.

Data like expiration dates, non-conformances, corrections, Standard Operating Procedures (SOPs), and masterbatches are among the many types of sensitive operational data that may be managed by a pharmaceutical ERP. To reduce the likelihood of recurring issues, ERP systems may help pharmaceutical companies enhance the robustness, responsiveness, flexibility, and intelligence of their supply networks.

This is achieved using pharmaceutical manufacturing ERP software, which increases operational transparency and facilitates the efficient running of production facilities of any size.

What Are the Challenges in the Pharmaceutical Industry?

Prominent challenges in the pharmaceutical industry are:

Assurance of Quality

Quality control is an essential part of the pharmaceutical industry. The pharmaceutical industry has a responsibility to ensure that its medicinal products are accurately represented to the public. New and better medications are being evaluated with more sophisticated analytical methods.

Lack of Qualified Workers

Qualified workers, also known as skilled laborers, are people who carry out technical or intellectual tasks that need in-depth knowledge of a specific field or discipline. The success of any business, but especially that of a pharmaceutical firm whose products are used to treat patients, is directly attributable to the caliber of its employees.

The pharmaceutical industry, in reality, is particularly in need of highly educated, trained, and experienced workers. It can only sustain its current rate of expansion by increasing its investment in skilled workers.

Lack of Flexibility in Manufacturing

One of the challenges in manufacturing is the lack of flexibility, especially in the pharmaceutical industry. As treatment indications become more refined and target specific patient populations, smaller batch sizes are required. With the increasing prevalence of rare diseases, it is crucial to explore various options in the development and production of effective medications.

However, companies capable of mass production often face difficulties in meeting the demand for rare illness treatments due to the need for manufacturing in extremely small quantities.

Disruption in the Supply Chain

The pharmaceutical industry is subject to strict rules and has a notoriously complex supply chain. It can't function without the close cooperation and transparent behavior of its many suppliers, no matter where they are located.

Workforce Optimization

Hiring decisions are impacted by cost concerns, and seemingly insignificant changes can have a big impact on income. When departments and teams within an organization work together, they are able to save time and ensure that they are all working towards the same goals. It is important to emphasize that optimizing the workforce maximizes employee benefits and, by extension, preserves efficiency in the pharmaceutical industry.

Manual Tasks

There are many operations that rely on the time and effort of our precious employees, yet they are all performed manually. A lot of their work is done on paper or in spreadsheets, which is inefficient in the current situation when information must move quickly and precisely. There is no assurance of precision when using spreadsheets. All of these steps being performed manually slow down the process significantly. The pharmaceutical industry, to realize its full potential, must make use of cutting-edge technology.

Regulatory Shifts in the Government

The pressing concern that arises regularly is how pharmaceutical businesses can stay up with the ever-evolving government requirements. The pharmaceutical industry is one that must always adhere completely to the established guidelines to prevent any kind of disobedience or noncompliance. It is challenging for the research and development team, the production team, and any other relevant teams to stay in sync with the new guidelines as long as the existing procedures are manual.

How Can ERP Help Pharmaceutical Companies?

Let's look at how ERP systems can resolve challenges faced by the pharmaceutical sector as a whole:

Administration of Recipes and Formulas

During the COVID-19 pandemic, there has been a heightened focus on improving medicine formulations, especially for rare ailments. Recipe and formula management pose challenges in the pharmaceutical industry, necessitating reliable technologies to handle this critical stage.

Implementing an industry-specific ERP system can effectively manage complex component formulae and medication formulations, offering solutions to these concerns.

Inventory

Effective stock and inventory management is vital for the success of pharmaceutical companies, given the extensive range of available drugs and the value associated with successful medicine formulations. Implementing an ERP system tailored for the pharmaceutical industry ensures accurate investment and stock level tracking, and facilitates inventory planning and warehouse management.

It offers benefits such as improved bin management, stock costing, and valuation. With all relevant data centralized in one location, managers gain a competitive edge in inventory management.

Purchasing

When it comes to taking care of orders, purchase management is just as crucial. An ERP's insights into supplier data, quotation comparison, etc., may be invaluable in supporting and directing businesses.

Pharma businesses may manage purchases based on projects, track orders from suppliers, and allocate funds for purchases with the help of the module dedicated to buying management.

Traceability, Batch Control, and Supply Chain Management

Efficient supply chain management in the pharmaceutical industry poses challenges due to the diverse customer locations and complex procedures involved. However, implementing an ERP system enables streamlined processes, end-to-end tracking, and enhanced traceability, reducing errors and reliance on paperwork. Real-time monitoring of temperature-sensitive medications and robust compliance measures further optimize operations, minimize costs, and ensure patient safety.

Costing and Quality Assurance for Products

A pharmaceutical ERP system manages cost contributors such as materials, production, and sourcing, enabling accurate pricing. Centralized and real-time data in the ERP aids implementation, supports decision-making, improves productivity, and ensures quality control in manufacturing.

Let's know more about the best ERP software for the pharmaceutical industry.

TranZact Can Simplify Operations for Your Pharma Business

An ERP system developed for your business's unique needs is the only way to guarantee streamlined operations. Clinical service delivery, financial management, supply chain management, legal matters, and more may all be better organized and optimized with the help of pharma ERP solutions.

TranZact ERP modules for the pharmaceutical industry provide solutions such as production and inventory management and enhance operations for pharma businesses, saving valuable time and resources.

FAQs on ERP for the Pharmaceutical Industry

1. How do you define ERP in the pharmaceutical sector?

ERP in the pharmaceutical sector is a comprehensive software system that integrates and manages various business processes, such as inventory management, production planning, supply chain management, and quality control. These systems streamline operations and ensure regulatory compliance.

2. Why is the pharmaceutical business interested in ERP?

Pharma ERP software enables the unification and standardization of the many steps involved in the production of pharmaceuticals. It also enables organizations to monitor vital processes including compliance, expiration, quality management, formulation, and pricing.

3. How TranZact is used in the pharmaceutical industry?

TranZact enables pharma businesses to streamline inventory management, product quality, regulatory compliance, and product traceability by automating end-to-end operations and improving recordkeeping and documentation. By utilizing its superior data analytics capabilities, manufacturers can see trends more rapidly and base their decisions on more reliable evidence.